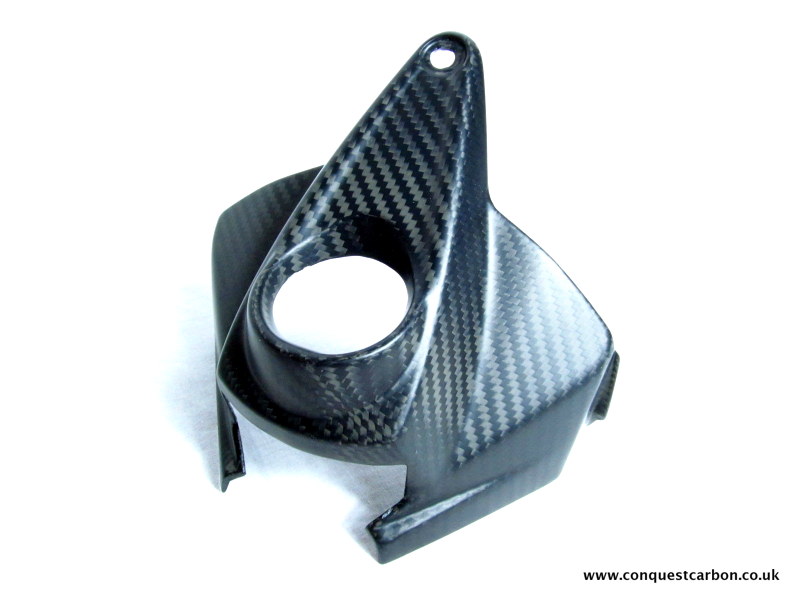

Aprilia Dorsoduro Carbon Fibre Performance Parts

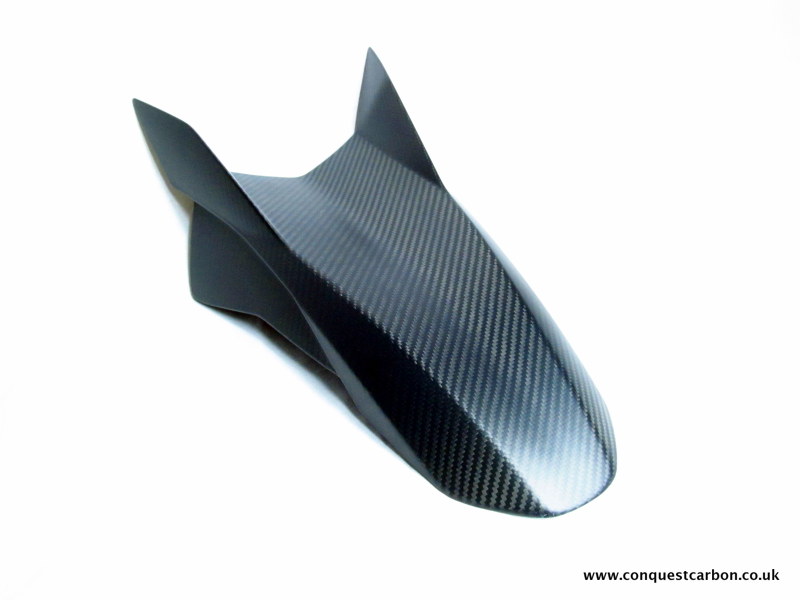

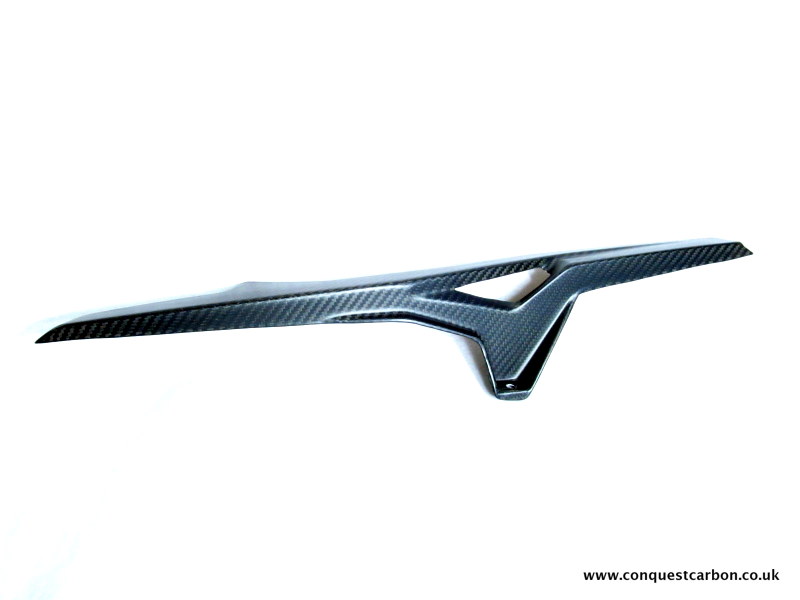

Aprilia Dorsoduro Carbon Fibre Performance Parts, satin/matte finish. Same weave as OEM Aprilia/Akrapovic carbon fibre. Manufactured using pre-preg carbon fibre & steel molds then cured in a high temperature autoclave oven creating a much thinner, lighter product without compromising on strength.

Autoclave production produces the best finish on the weave, keeping the carbon fibre in a more level and constant pattern, preventing kinks and stretching. Finally laser cut using a high pressure water jet to produce a clean edge & polished by hand.

Using 2 mm, 3K twill weave carbon fibre with an epoxy resin providing both excellent strength and flexibility, UV treated lacquer which will help to keep your Aprilia carbon looking new for years.

Features:

– High quality clear finish will add a custom, race look to your bike

– Made by using high quality epoxy resin and high quality carbon fibre

– Auto clave produced

– UV resistant varnish

– Same OEM carbon fibre weave

– Make your bike stand out from the crowd

- Published in Conquest Racing Parts

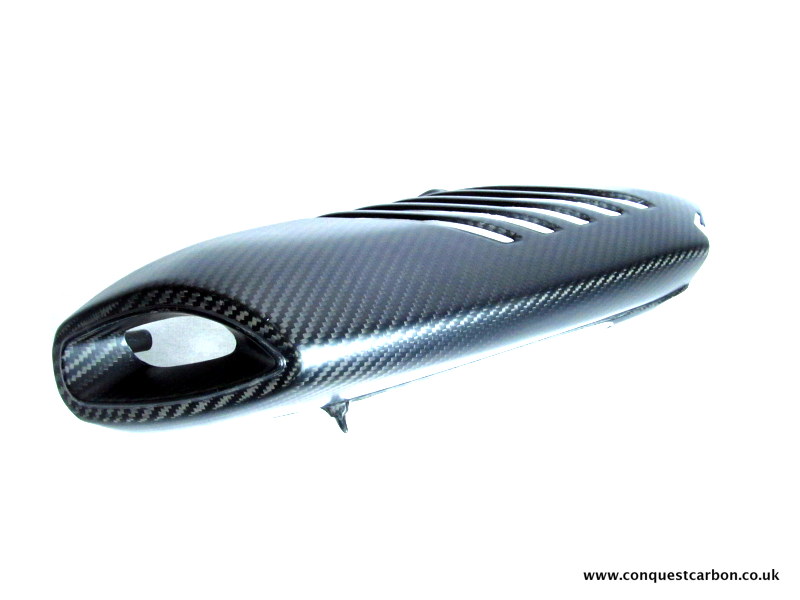

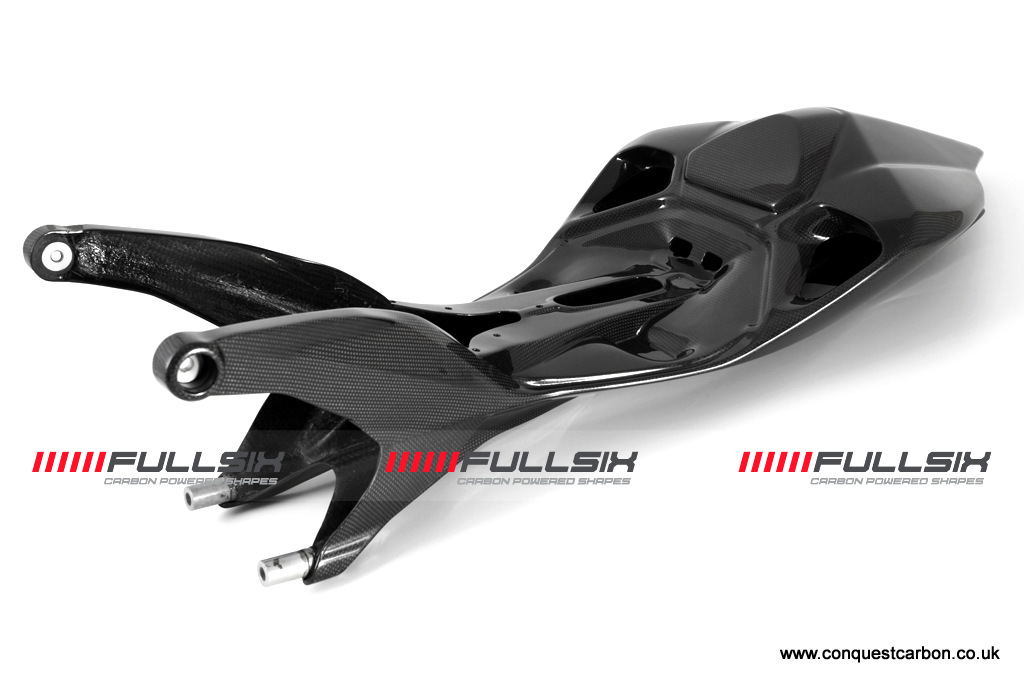

Special products designed specifically for Ducati Monster 696 796 1100 by Fullsix Carbon

Special products designed specifically for Ducati Monster 696 796 1100 by Fullsix Carbon,

We are pleased to announce that Fullsix have just created a whole new line of carbon fibre products specially designed for the Ducati Monster 696 796 1100 range.

fullsix-carbon-fibre-ducati-monster-796-1100/

In collaboration with renowned designer John Keogh, the FullSix team would like to introduce the »FullSix Monster«, a stylish carbon fiber reinterpretation of the classic Ducati Monster. Sophisticated yet muscular and sexy, the FullSix Monster is a showcase of John Keogh’s design talent and FullSix’s carbon elegance. The result is a perfect look, precise fitting and supreme part quality which captures and augments the spirit of Ducati.

Designed by John Keogh, crafted by FullSix.

John Keogh

John Keogh brings nearly 20 years of professional motorcycle design experience and critical acclaim to CDT Group and FullSix. Trained as an automotive designer in the UK and Switzerland, John is an authority in motorcycle design and regularly contributes articles and drawings to motorcycle magazines worldwide.

In addition to designing personalized prototypes such as the Ducati Terminator, Vee Two Squalo and SuperSqualo, John has collaborated with OEM manufacturers such as Triumph and Buell/Harley-Davidson on projects such as the radical Buell Firebolt and Lightning. One will also find John’s creations on the racetrack as well, having worked with motorcycle race teams such as Roberts GP and WCM Yamaha, as well as automotive race teams such as Lola, RML and Caterham.

Collaboration & Design

In 2008, CDT Group has ranked among the top global manufacturers of high quality carbon fiber parts in the automotive and motorcycle industry. In joining forces with John Keogh, CDT Group has created the FullSix Monster. Drawing inspiration from the original Monster design and incorporating John’s organic approach which focuses on extracting a subject’s original design elements and producing a new creation that is both complimentary and yet surpasses the original, the FullSix Monster demonstrates CDT Group’s pursuit of world class carbon fiber design.

Free from the rules and restrictions imposed in professional racing, the FullSix Monster fully showcases John’s creativity. Blending Galluzzi’s Monster with his own provocative ideas, John applied his »fast and dirty« design approach to adorn our favorite Italian motorcycle with sex appeal and carbon elegance. »It is a Monster with a special touch« says John Keogh, »This is a major step forward.«

- Published in Conquest Racing Parts

Conquest Ducati Panigale 1199RS The Build Has Started

Conquest Ducati Panigale 1199RS The Build Has Started, we have started the build on our Ducati Panigale 1199s.

We will update this post regularly with the progress of the build and we hope by late April she will be complete, we hope you enjoy watching……………..

We have decided to continue with the carbon/gold/silver theme and I really hope we pull it off! So far we have had delivery of all the carbon parts and today we have started on the nose cone.

We have added Panigale 1199R brushed steel decals, venture shield protection, Puig light smoked high screen & Pro-Bolt screen screws in black.

The side fairings and tank……..

New parts, CNC Racing, Ducabike & Pro-Bolt……

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/09875a0ce05aa3d61d27a05058011511.jpg)

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/12e4fc0f5a6dab60268c44826eaba259.jpg)

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/2f02e26db9f76f2adef20404b15fcfa4.jpg)

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/b82cdfc6f813272933a8fc1dbefa3320.jpg)

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/527ba6fbc470488cdd4364b2d310fcd9.jpg)

Evotech rad guards & tail tidy……

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/a7371a49509d28333bd67a3f6ef7b352.jpg)

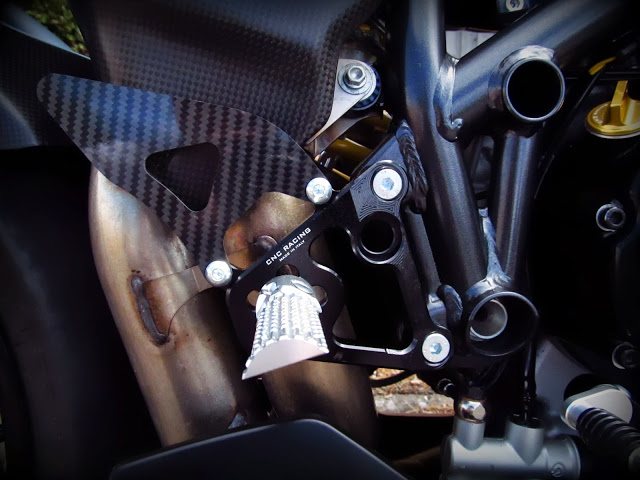

Just arrived, CNC Racing Ducati Panigale RPS rearsets……..

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/7fa91d53da936342f1c7823be0cf515c.jpg)

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/1d63bea21063c9f4ba5e2d4b0769aaa2.jpg)

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/1c5a390ff55477a3559156dd6d927d05.jpg)

![[IMG]](https://conquestracingltd.com/wp-content/uploads/2020/06/bfc7ba3d26293cec53d5dd79aa2f5e96.jpg)

At the weekend we made a start to the build. We have recorded 85% on a time lapse camera which after we have done some editing we will post on here.

Here is a sneak preview of the work so far:

RHS CNC Racing RPS rearset fitted, these are the normal shift type (race shift also available) they are a work of art and cant wait to put them to use.

We also added exhaust wrap to the exhaust as this gets incredibly hot and as we want to use a carbon guard we decided that apart from getting it ceramic coated then this is second best.

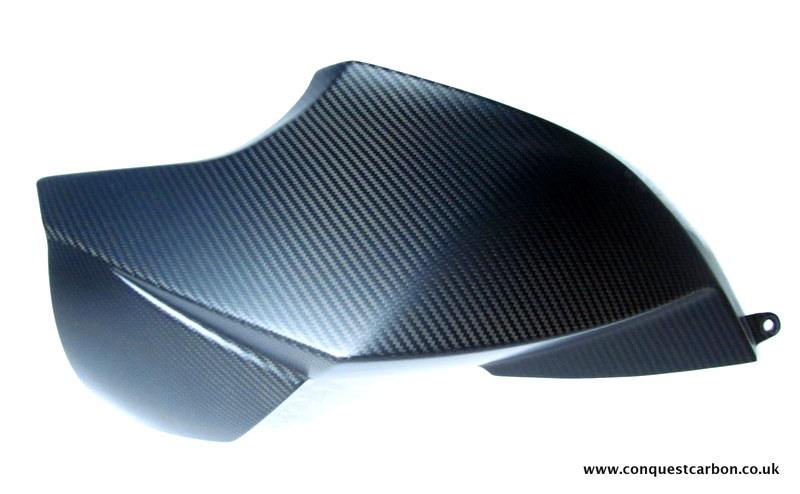

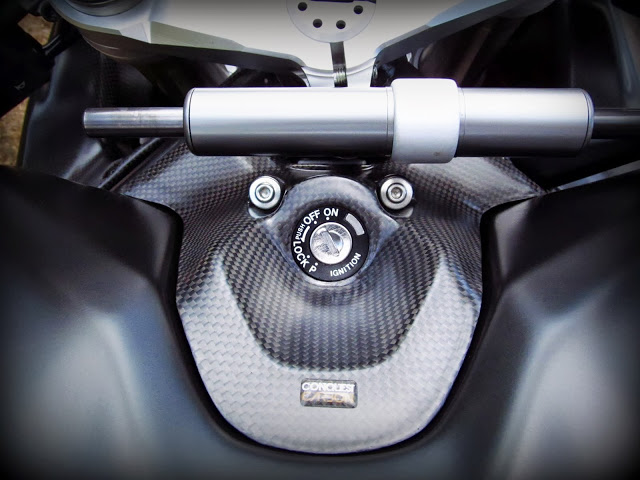

In the second picture below we have fitted the satin/matte carbon electronic covers, Samco hoses, satin/matte carbon V-panel, Evotech performance upper & lower rad covers, satin/matte subframe covers, CNC racing upper frame plug and engine cam cover. We have also swapped all bolts for titanium/stainless steel.

In the picture below we have installed the carbon nose cone, satin/matte carbon front instrument cover, satin/matte clock surround & satin/matte headlight/clock holder.

RHS CNC Racing RPS rearset fitted, these are the normal shift type (race shift also available) they are a work of art and cant wait to put them to use.

To be continued………………….

- Published in Conquest Racing Parts

Aprilia RSV4 Carbon Fibre

Aprilia RSV4 Carbon Fibre is manufactured using pre-preg carbon fibre & steel moulds then cured in a high temperature autoclave oven creating a much thinner, lighter product without compromising on strength.

Auto-clave production produces the best finish on the weave, keeping the carbon fibre in a more level and constant pattern, preventing kinks and stretching.

Finally laser cut using a high pressure water jet to produce a clean edge & polished by hand.

Using 2 mm, 3K plain weave carbon fibre with an epoxy resin and glass backing providing both excellent strength and flexibility, UV treated lacquer which will help to keep your Aprilia carbon fibre looking new for years.

Made from the same Aprilia carbon fibre weave, so why pay factory prices and have your bike look the business without the high OEM costs.

VIEW PARTS IN OUR SHOP, CLICK HERE

- Published in Conquest Racing Parts

Fullsix Carbon Fibre – CDT Carbon Fibre Group – Conquest Carbon

Fullsix Carbon Fibre – CDT Carbon Fibre Group – Conquest Carbon now dealers for their stunning carbon creations.

Click here to view their parts

CDT Group

Since 2008, CDT Group has been one of the world leaders in the production of high quality carbon fiber parts, both as an original equipment manufacturer (OEM) and as an aftermarket manufacturer. We are among the world’s leading brands in the automotive and motorcycle industry and we are passionate about developing the best products. Our young and highly qualified staff is the driving force behind our commitment to offer you only the most innovative products. We guarantee only the best for your motorcycle: a perfect look, precise fitting, outstanding performance and supreme quality. Our passionate pursuit of perfect carbon fiber parts has consolidated our position in the world market.

The FullSix brand was designed with the desire to achieve perfection. Through the use of autoclave technology and new composites we guarantee our customers only the best carbon fiber products. Our innovative manufacturing processes make us the only company in the market which is able to ensure flawless production. The quality of our manufacturing processes is reflected in our latest cutting-edge product from Slovenia and we have achieved something no one thought possible: a perfect one piece carbon fuel tank.

Vision

Our vision is to become the world leader in the production of the highest quality class of carbon fiber parts for motorcycles. We aim to achieve our goal step-by-step, focusing on technological innovation, hard work and a constant pursuit of perfection. From Slovenia, the home of many world recognized brands in the motorcycle industry, we are introducing the highest quality range of carbon fiber products to the world market. Our innovations in the field of manufacturing and production, such as our proprietary Autoclave Composite Monocoque (ACM) technology, make us a pioneer in the industry.

Fullsix products

FullSix carbon fiber parts guarantee an excellent appearance and perfect manufacturing. By using state-of-the-art technology and an innovative blend of materials, we assure you that our parts will upgrade your motorcycle both visually and in terms of performance. We have paid particular attention to ensuring that all carbon fiber parts are UV protected through the use of special lacquers, as we know that our customers desire eternal beauty and perfection.

We accept no compromises, we take no shortcuts. Careful attention is paid to details to achieve that final sparkle that is the difference between good and supreme products. Good looks are not all we are proud of. Using state-of-the-art technological solutions, we ensure that each part is completely compatible with your motorcycle. All parts and accessories that are needed to install your Fullsix product are included, so you can install every piece yourself.

The uniqueness of our products is not just an advertising slogan, but the underlying philosophy of our company itself. Since we believe in providing only the best for your motorcycle, we have developed a unique production monitoring system that ensures that all Fullsix products are manufactured according to the latest protocols and “best-in-the-industry” standards. Through the use of unique barcode technology, CDT Group is teh only company in the market that is capable of tracing products through the entire manufacturing process, resulting in products that you completely trust.

Fullsix stands for perfect looks, precise fitting, outstanding performance and supreme quality.

CDT Group is known worldwide for its quality parts which are made from only the best materials and technology. We use only five star materials, shaping them into real pieces of art with our precisely engineered autoclave technology.

Our products stand out in terms of quality, as every step of the production process can be traced and monitored using barcode technology. This enables the company to have complete control over the production of its products, so that each and every product which carries the FullSix logo has consistency and quality that can be fully trusted.

All steps of of the production process are manufactured to perfection: from the cutting of fabric to the final paint job.

Our collaboration with world renowned research institutes, such as the Jožef Stefan Institute, has placed us amongst the most innovative enterprises in the field of composite manufacturing. With scientific precision we carefully determine the properties of the materials which will enhance the visual appearance and performance of your motorcycle.

This enables us to guarantee flawless production processes and the top quality attributes expected of FullSix products.

ACM Technology

CDT Group is the inventor of Autoclave Composite Monocoque (ACM) technology and is the only company in the world that is able to produce a high decorative finish complex-shaped closed-body monocoque out of a single carbon fiber-based unit (e.g. a one-piece fuel tank for motorcycles). This technology is directly applicable for fabrication of various one-step closed-body monocoques, where no cutting, trimming and bonding is required. In contrast to conventional bonding, ACM technology provides monocoques with supreme mechanical strength, chemical resistance and a flawless finish.

Monocoque fuel tank

Despite claims that it was impossible, we have successfully utilised our innovative ACM technology in manufacturing a flawless hollow carbon fiber part. We have developed a tank that solves the problems that plagued carbon tanks in the past – meaning they were only bought by the bravest of motorcyclists. Rest-assured, today you can forget the difficulties associated with the tanks made of two parts. You no longer need to be concerned about leaking seams which made carbon fiber fuel tanks the most dangerous part of a motorcycle.

Our groundbreaking ACM technology represents a novelty in technology and production – a special innovative technological process developed by CDT Group for manufacturing hollow pieces without joints and adhesives.

The CDT Group’s R&D team is constantly monitoring and improving the technological procedures used for the production of high-tech carbon-fiber composite products. Our R&D is orientated towards functionalization of high-quality carbon-fiber composite parts and launching of novel products exhibiting state-of-the-art properties. Current major R&D projects are focused in the following strategic areas:

– The development of Autoclave Composite Monocoque (ACM) technology.

Our ACM technology represents a breakthrough in technology and production – a special innovative technological process developed by CDT Group for manufacturing every hollow piece without joints and adhesives.

– Utilizing nanotechnology to produce superior parts.

Through the use of nanotechnology, CDT Group is able to produce carbon fiber parts that have enhanced properties that offer superior value compared to competing products (e.g. scratch resistant clear coating).

– Development of photovoltaic carbon-fiber composite components for lightweight solar-powered electric motorcycles.

The major advantages of electric motorcycles in contrast to vehicles with conventional combustion engines are extremely low noise pollution and zero-carbon emissions. Electric motorcycles have linear torque curves which are a major advantage in relation to conventional engines. Acceleration is vibration free, resulting in better track traction and lean orientation. When a motorcycle is designed as a self-sustaining energy system (e.g. solar-powered), the weight of these electrically driven vehicles need to be minimized. Here, carbon-fiber composite components are preferred due to their high strength-to-weight ratio. Our goal is to develop a platform composed of flexible photovoltaic cells integrated with carbon-fiber composite modules with high-aesthetic standards which are able to convert light into electricity. This technology can be adapted to become applicable in various low-weight mobile applications where light-electricity conversion is utilized.

- Published in Conquest Racing Parts

Shifting into 5th gear with WordPress SEO

Shifting into 5th gear with WordPress SEO,

Our SEO company has kindly been in contact due our hard work at making our website SEO friendly. Below is a short story of our success with Squirrly’s SEO……..

Conquest Carbon is a great company for all you passionate motorcyclists out there, but the appealing sound of the engine was not enough to get across to their online audience. That’s why Squirrlys plugin for WordPress Seo gave them the helping hand in getting on track to become as popular as Valentino Rossi.

Who are Conquest Carbon?

They are a small business near Wimborne that transformed their passion for motorcycles into a successful company. They realized they don’t simply love the sound of the motor, but the perfecting of the engineering masterpiece and the trill of motorcycle speed races.

Their shop specializes in performance parts for Sport bikes and carbon fiber that can be professionally fitted for your motorcycle. The attitude of perfecting the ride to accentuate the adrenaline rush, was there even when they were thinking of WordPress SEO. They operate a policy of 100% customer satisfaction, proved by their work with motorcycle manufactures such as Ducati, Triumph and Yamaha and their showroom and site prove it too.

Squirrly, speeding up the traffic

When they choose the Squirrly plugin for better WordPress SEO, they weren’t searching for the same rush as from being in a racing competition. But by using the Live Assistant they make sure that every article on their blog is at high performance, with the best title and keyword density. It is like the pit garages where you make sure everything is working at high performance before the WordPress SEO big race, getting more people on your site and in your online shop.

The Squirrly keyword research tool helps them keep their motorcycle site clean. It doesn’t matter if it’s presenting reviews of their products or writing about the latest speed race, they always know which words are best suited to bring the right customers to their site. And it doesn’t stop here. In WordPress SEO Squirrly offers detailed analysis about your ranking. About the traffic you get on your every post and on the overall site. How well you stand in social media and the power your content page can generate on the web, are just a few extra information that come in handy to the content creators.

And now each week on their email they get the Audit of their site to tell them how they’ve improved in the last weeks race for traffic. They get to have specific statistics on their site and it’s evolution. They also get tips, so things are pretty straight forward, just how they like to make things for their own customers.

The real results in WordPress SEO

But performance is not credible if not measured. So let’s put it into perspective. Squirrly helped Conquest Carbon perfect their skill in writing content an getting more audience, by increasing their traffic by 500% in just a few months. And the important part is that it got them the right people that are interested in speed racing and motorcycles. Those people are the ones that are going to become their customers in the future. The ones that will appreciate their showroom and their professional attitude.

Our plugin refines their content, so their passion for the adrenaline that only motorcycle rides give you, transpires. We want each one of you, interested in motorbikes to get closer to them. The sooner you find them, the sooner you’ll get on your better performing ride.

- Published in Conquest Racing Parts

CNC Racing Parts

CNC Racing Parts sold by Conquest Carbon.

About CNC Racing

Made in Italy, exclusively manufactured from solid materials utilizing advanced technology makes it possible to create a line of motorcycle accessories to enhance the features most suitable for your particular bike without ignoring quality or precision. Driven by passion, research and development activities are conducted in-house to ensure greatness as we seek to push the envelope of what’s possible with innovative projects and collaboration with leading (and World Champion) racing teams.

The advanced technologies increasingly looking to the future have led the company to seek a line style of work and passion for two wheels projecting and creations of motorcycle accessories.

All this is based on research of innovative and original, following the line of the Italian brand par excellence. motorbike accessories created by lines drawn are born from ideas, quickly becoming a reality thanks to technological tools inside the company.

The articles come from well-defined and structured phases: the creation of new designs, switched to CAD / CAM applications, the choice of material, until the construction of prototypes and testing of model. Our motorcycle accessories are born from an idea, a simple sketch that is then developed in engineering departments, where points are plotted basic building.

The project follows the mechanical preparation of the construction parameters passing first through the CAD / CAM technology by going to the field of machining where does the actual product. Each phase is studied and followed with the utmost professionalism following the step by step creation of a high quality product.

The quantity of our motorcycle accessories have no limits: we can build small, medium and large series, each customized to the client’s request, in every color and type of finish, the customer only has to choose from. Our motorcycle accessories are tested, created with safe material and geometric shape on the top with innovative style motorcycle staying in the same way objects of unquestionable quality.

- Published in Conquest Racing Parts

Ducati Street Fighter Carbon Fibre Parts

Ducati Street Fighter Carbon Fibre Parts by Conquest Carbon.

We use the very latest carbon fibre autoclave F1 technology giving you a beautiful, strong & very light replacement to the standard parts. We give you the chance to obtain the parts that factory teams use, allowing you to build the individual superbike of your dreams. We are also suppliers of CNC Racing parts made in Italy, exclusively manufactured from solid materials utilizing advanced technology makes it possible to create a line of motorcycle accessories to enhance the features most suitable for your particular bike without ignoring quality or precision.

Our Carbon fibre parts are manufactured using pre-preg process and finished in a high temperature autoclave oven. This provides a much thinner, lighter product without compromising on strength, it also provides the best finish on the weave keeping the fibre in a more level and constant pattern. The molds are made from steel and the parts are laser cut using a high pressure water jet. And finally polished by hand. Using 2 mm, 3K twill weave carbon fibre with an epoxy resin and glass backing providing both excellent strength and flexibility, UV treated lacquer which will help to keep your carbon looking new for years. Made from the exact weave that Ducati themselves use, so why pay factory prices and have your bike look the business without the high OEM costs.

- Published in Conquest Racing Parts

Ducati 848 1098 1198 Carbon Fibre Parts

Ducati 848 1098 1198 Carbon Fibre Parts by Conquest Carbon.

We use the very latest carbon fibre autoclave F1 technology giving you a beautiful, strong & very light replacement to the standard parts. We give you the chance to obtain the parts that factory teams use, allowing you to build the individual superbike of your dreams. We are also suppliers of CNC Racing parts made in Italy, exclusively manufactured from solid materials utilizing advanced technology makes it possible to create a line of motorcycle accessories to enhance the features most suitable for your particular bike without ignoring quality or precision

Our Carbon fibre parts are manufactured using pre-preg process and finished in a high temperature autoclave oven. This provides a much thinner, lighter product without compromising on strength, it also provides the best finish on the weave keeping the fibre in a more level and constant pattern. The molds are made from steel and the parts are laser cut using a high pressure water jet. And finally polished by hand. Using 2 mm, 3K twill weave carbon fibre with an epoxy resin and glass backing providing both excellent strength and flexibility, UV treated lacquer which will help to keep your carbon looking new for years. Made from the exact weave that Ducati themselves use, so why pay factory prices and have your bike look the business without the high OEM costs.

Our Carbon fibre parts are manufactured using pre-preg process and finished in a high temperature autoclave oven. This provides a much thinner, lighter product without compromising on strength, it also provides the best finish on the weave keeping the fibre in a more level and constant pattern. The molds are made from steel and the parts are laser cut using a high pressure water jet. And finally polished by hand. Using 2 mm, 3K twill weave carbon fibre with an epoxy resin and glass backing providing both excellent strength and flexibility, UV treated lacquer which will help to keep your carbon looking new for years. Made from the exact weave that Ducati themselves use, so why pay factory prices and have your bike look the business without the high OEM costs.

- Published in Conquest Racing Parts