Conquest Carbon – Racing towards 2015 with Nicky Wilson 48

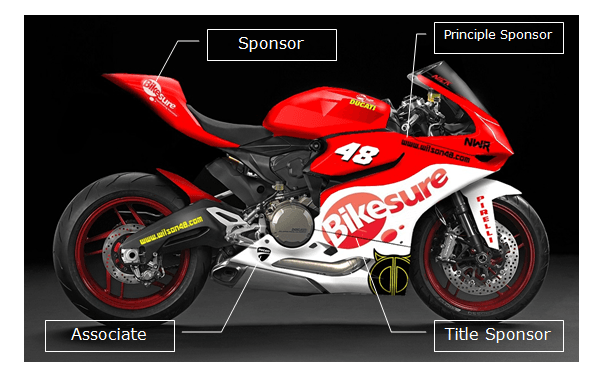

Conquest Carbon – Racing towards 2015 with Nicky Wilson 48, at the start of 2014, we agreed to support Nicky Wilson Racing (NWR), and to supplying the team with some of quality components available on our website. Associating Conquest Carbon with NWR who race in the Ducati TriOptions Cup on the new Ducati Panigale 899, was an ideal showcase for our products at the track.

Working with NWR through social media has increased our brand awareness and increased sales quantifiably. Following this success, we are looking to increase our involvement with the team in 2015 by attending the races with our carbon demo bike and show stand.

We are also keen to help the team find further sponsors and partners for the 2015 season: We at Conquest Carbon can personally vouch the work ethic and professionalism NWR brings to their sponsors, and the benefits that can be had from a partnership with them.

Therefore if you are interested or know of anyone who might want to get involved with the team in 2015, here are some of the other benefits which can be had: Association with NWR will increase awareness of your brand within the motorcycling community by engaging with bike fans and owners through having a physical presence at each round of the British Superbike Championship and one round of the World Superbike Championship.

Example:

Sponsors can use this association as leverage to drive footfall into store or increase online traffic to their website. A partnership also creates unique news content that can be used across all media channels such as websites, newsletters, social media and advertising. At the track you can experience racing from the teams perspective in the race awning and enjoy the Ducati UK hospitality facilities.

Sponsor packages are available on request to suit all budgets. Please contact Nicky directly on +44 (0)7980 443961 or via nicky@wilson48.com

- Published in MotoGP, Motorcycles, Nicky Wilson #48

Inside Lieb Speed How To Manufacture Ducati Carbon Fibre Parts

Inside Lieb Speed How To Manufacture Ducati Carbon Fibre Parts, carbon is a fascinating base, its applications almost no limits because of its excellent material properties and unique look.

Are you interested in what manufacturing techniques, we manufacture our carbon fiber parts? We’ll show you how.

Model Creation:

Basis for making a carbon fiber component is a form (= tool). To produce a tool again a model / original model is required.

There are several ways to create models for motorcycles:

The usual method is an original part – eg a plastic wheel cover – to use it. Because the original model for producing a plurality of tools to be used, the making of a temporary tool is initially (usually made of GRP in the hand lay-up) is necessary.

This temporary tool then the master model is established, the further modified in a complex work process needs to be primed and painted.

Another widely used method for model fabrication and also to realize their own ideas and unusual design is the Modelliertontechnik. Here, right on the motorcycle with the modeling clay (also called Clay) models and then made as in the first method with a makeshift tool the original model.

In the professional production method (which we mostly use), the original model (constructed with a special program or be scanned) based on CAD data with a CNC milling machine from the block millable special plastic such as Ureol milled.

This method is the standard method of Formula 1 and Moto GP.

(CAD model of a clutch cover)

(Model production on 5-axis CNC milling machine)

When time is of particularly fast, a tool can be machined directly from an aluminium or epoxy block.

(Aluminium tool “Mirror Plates Ducati Panigale”)

The model of aluminium or epoxy now serves as the master model.

Mold Making:

In order to withstand the extreme conditions but in an autoclave (3-7 bar pressure and 100-140 ° C temperature), the tools should either aluminum (is the handling larger workpieces bit difficult) to be built or even carbon fiber.

We use vacuum infusion process for making a carbon fiber tool.

This method is still relatively new (about 10 years) and was developed in the aviation industry. This method allows to build very high quality and very durable tools that withstand several hundred cycles in an autoclave without sacrificing quality.

However, the vacuum infusion process requires a great deal of experience. We work with because it is not only the best but also the unbedenklichste currently for health methods to produce a carbon fiber tool.

(Vacuum infusion of a front fender)

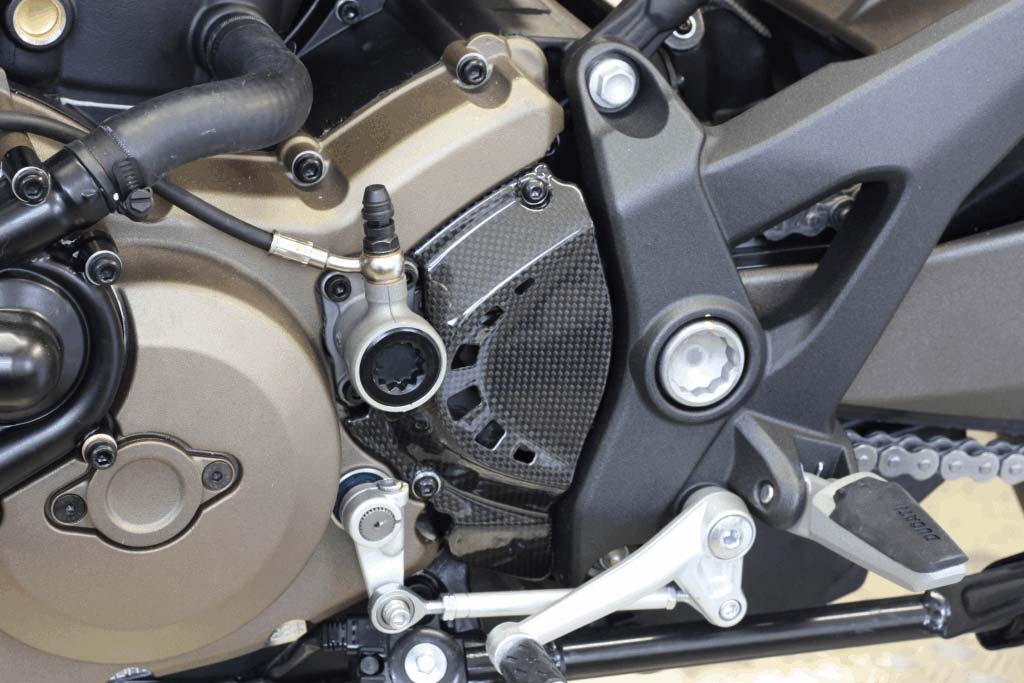

(Product made of carbon fibre)

For motorcycle component production, we exclusively to the autoclave process. For this purpose (prepreg epoxy prepreg carbon fiber fabric with =) are cut tailored blanks of different carbon fiber Prepreggeweben, which are then inserted, using a Laminierplans in the respective tool.

A complex component may consist of more than 50 different location blanks, so we number the items. The material-saving cutting ensures used for nesting software with us.

(Nesting software for optimized cutting material)

The created data (Cut-file) will be sent to our CNC cutter, which cuts the individual parts and features simultaneously.

(CNC Cutter)

The individual prepreg blanks are placed in a predetermined order (using the Laminierplans) by hand in the previously treated with mold release agent. Because the prepreg layers are processed to optimally only in a narrow temperature range, which takes place in an air conditioned room with us. Is it too cold, not stick the individual layers in the mold; it is too warm, they are very sticky and are then very difficult to process.

(prepreg layers in the tool)

Inserting the individual prepreg layers follows a so-called vacuum structure: On the fabric has a release film and a bleeder is placed the entire tool is packed in a vacuum bag which is hermetically sealed. The vacuum bag is connected to the integrated therein vacuum pump in the autoclave.

This can be continuously monitored during the curing process, whether the vacuum bag remains sealed, each component has its own vacuum hose.

The autoclave was sealed and the cycle is started. Each cycle lasts depending on the used prepreg material about 3 – 4 hours. In each cycle, a preset program controls the temperature and pressure conditions in the device.

After completion of the cycle, the tool is removed from the vacuum bag, the vacuum structure is removed and the cured carbon fiber component mold.

The outer contours still be trimmed and drilled holes as needed or milled air inlets on the components.

This is done on our 5-axis CNC milling machine, because only there an optimal accuracy of the components can be achieved.

Also for an apparatus must be built for each individual component on which it is fixed by means of vacuum. In addition, a program will be created also for each individual component. We use our Tebis CADCAM system.

If there are no CAD data of a component, we digitize the component contour with a 3D measuring arm directly from a pattern component.

(5-axis CNC milling machine in action)

After completion of the program on the CNC milling machine, the component is removed and trimmed manually.

If the respective component of several individual components or are still various mounts or metal bushings glued, hiking the parts in our department adhesive.

Here the carbon fiber parts with special 2-component adhesives bonded to a doser (special equipment that applies adhesives with programmable dosing volume). In order to obtain a very high dimensional accuracy and here we use quite often very specific arrangements made by us adhesive molds.

(Adhesive side panels Ducati Diavel)

After cleaning, the first quality control is performed before the component in our painting department shall proceed.

For painting the component is cleaned meticulously and the surface slightly rough; so last release agents are removed. We use this small, winding components wet blasting machine, large components are prepared by hand.

On a special paint wagon, the component runs in the paint booth. Here the clear coat is applied with a spray gun. We use an OEM paint (with car manufacturer approval) in gloss and matte finish.

The paint shop is one of the most important areas of our production. The coating not only serves to protect the component against environmental influences such as UV radiation and moisture, but also gives it this incomparable three-dimensional carbon look.

After drying, the painted parts, a further quality control, which eliminates nor any trapped dust. The latter are very rare with us; our professional paint booth with filtered air pressure prevents it reliably.

The Result is a high quality carbon fiber component that we have made with skill and experience and great technical effort accurately.

The device is ready to ship and will bring joy to our valued customers for many years.

- Published in Conquest Racing Parts, MotoGP

Ducabike Parts For Ducati

Ducabike Parts For Ducati..Ducabike are an Italian company wh0 specialise in everything Ducati. We their state of the art manufacturing using the very latest in R&D brought together to produce some beautifully finished bolt on accessories for your Ducati.

Click on the shop below and select your Ducati to see more of their creations.

DUCABIKE is synonym of passion for motorbike and in special way for Ducati® bikes. Bikes can be rich and precious from owner based on own taste and need.

DUCABIKE born with this target, create the best in the market to make extraordinary your Ducati®.

DUCABIKE project, develop and trade the products, based on experience in all the years on road and in racing to do every effort to give the maximum reliable and guarantee on products, find the design and the best performance, utilise support of our prepared technicians and the best test pilot, employing the best materials and the innovative technology in the motorbike world, this offer products always at the top.

- Published in Conquest Racing Parts

2015 New Ducati Panigale 1299

2015 New Ducati Panigale 1299, Ducati’s flagship Panigale superbike has been given a technical and technological makeover aimed at keeping the road bike ahead of a very strong field of rivals in 2015, and the racing machine up the front of the Superstock grid.

As MCN revealed weeks ago there are now two different engines in the 1299 range; one for the standard 1299 and S models that have the 1285cc variant, and another for the R model which keeps to 1198cc to comply with Superstock and Superbike racing regulations, and benefits from a host of upgrade parts first seen on the high-spec 1199 Superleggera model launched last year.

All of the 1299 models get a redesigned tailpiece and an all-new exhaust system that’s lighter than the outgoing model’s. At the heart of the standard and S models is the new 1285cc version of the Superquadro V-twin that was first seen in the 1199 Panigale launched in 2011. Power is now a claimed 205bhp and the torque a monstrous 106.6lbft at 8750rpm – all wrapped up in a package that weights a mere 166.5kg.

Like the Multistrada 1200, the new 1299 has the Inertial Measurement Unit (IMU) which works to control and process all of the other electronic systems including cornering ABS, anti-wheelie, a new quickshifter that works for both up and down changes, semi-active suspension, engine braking control and traction control, along with the riding modes. The quickshifter also features a bar-mounted two-button controller on the left handlebar which allows the rider to effect up and down gearshifts without using the gear lever or clutch.

Creating balance

The new 1285cc engine produces 10% more torque and 10bhp more power thanks to the 87cc extra capacity, with the pistons now a vast 116mm in diameter, while the compression ratio has increased to 12.6:1. Those pistons, rings and pins have been redesigned and the whole engine (still with a 90-degree Vee angle, and still a structural part of the bike) has been rolled back in relation to the horizontal measurement to improve the weight distribution between front and rear.

In addition, the steering head angle has been altered by 0.5degrees to 24 degrees from 24.5degrees and the trail has been reduced from 100mm to 96mm. The swingarm lower pivot point is also now 4mm lower.

UK on the road prices:

Panigale 1299 £16,995

Panigale 1299 S £20,795

Panigale R £28,995

- Published in Motorcycles

New Ducati Monster 821 1200 Stripe 2015

New Ducati Monster 821 1200 Stripe 2015, Over 290,000 Monsters have been sold since launch in 1992, and now the Italian firm have added another couple of options to the range with two new ‘Stripe’ models. The Monster 821 Stripe and Monster 1200 S Stripe versions are characterised by a red colour scheme with a white double side-stripe on mudguard, tank and passenger seat cover. Both bikes also have a red-painted nose fairing, while the Monster 821 Stripe is also equipped with adjustable forks and the Monster 1200 S Stripe with a Ducati Performance undertail plate holder and carbon belt covers.

UK on the road prices:

Monster 821 Stripe £9495

Monster 1200 Stripe £13,995

- Published in Motorcycles

2015 Ducati Multistrada 1200

2015 Ducati Multistrada 1200, Ducati’s big-selling Multistrada 1200 gets a massive overhaul for 2015, making it an almost all-new bike, with variable valve control engine, all-new electronics, revised styling and improvements to rider comfort and convenience. There are two models – the standard 1200, and an ‘S’ model which also includes the D-Air version that links to Dainese’s electronically-controlled rider airbag system.

The overall appearance of the new bike is still very recognisably Multistrada, but the new Ducati Variable Timing (DVT) version of the Testastretta 1198cc V-twin is now producing 160bhp at peak power, and with gains throughout the range thanks to the engine’s ability to adjust the valve timing to suit both low rev torque and higher rev power.

Other new features include an Inertial Measurement Unit (IMU), which works with the electronics by measuring roll, yaw and pitch angles as well as the rate of transition between them. This system works with the 1200’s cornering ABS, wheelie control, eight-stage traction control and the semi-active Skyhook suspension taken from the outgoing model. Cruise control is now standard on all models and a new multimedia system connects the bike to a smartphone by Bluetooth and allows interactivity between the bike and the phone for things like calls and text message notifications, and it even has a full LED headlight with the ability to light around corners.

Variable benefits

Ducati revealed they would be using the DVT system on a secret new 2015 bike three weeks ago, and MCN spy shots confirmed two weeks ago that it would be the Multistrada 1200. The system works to independently vary the timing of the camshaft that control both intake and exhaust valves according the best solution determined by the revs.

The intention is to provide the best of both worlds with low to medium rev torque and engine smoothness but higher rev power and performance. It works to constantly vary the degree of valve overlap so it’s always optimally matched to engine revs.

The DVT system is divided into two parts: an external housing rigidly connected to the timing belt and an internal mechanism connected to the camshaft. The internal mechanism can rotate and advance or retard the valve timing depending on the oil pressure in control chambers, which is adjusted by dedicated valves according to the engine revs and load.

New electronics

The IMU is the control and monitoring unit that processes and governs all the other electronic systems, including the traction control, anti-wheelie, cornering ABS, cornering lights and the four riding modes along with the Skyhook semi-active suspension.

The riding modes are carried over from the outgoing model with Sport, Touring, Urban and Enduro modes. They range from offering the full 160bhp in Sport and Touring but drop to 100bhp in the other modes. ABS, traction control, the semi-active suspension, ride height, throttle response and wheelie control are all adjusted according to each mode.

Rider comforts

A larger front fairing, bigger (adjustable) windscreen, altered riding position and re-profiled height adjustable seat are, Ducati claims, big contributions to the improvement of rider comfort on the new Multistrada 1200. The seat now adjusts between 825mm and 845mm and the handlebars are rubber mounted to reduce vibration. The 12v power sockets have also been moved to more convenient locations.

UK on the road prices:

Multistrada 1200 £12,995

Multistrada 1200S red £15,595

Multistrada 1200S white £15,795

- Published in Motorcycles

2015 New Triumph Street Triple RX

2015 New Triumph Street Triple RX, The naked middleweight market has been dominated by Triumph’s Street Triple ever since it first launched in a maelstrom of surprise and giggling back in 2007.

The R model only added to the depth of the naked’s talents, and both models continue to attract a seemingly inexhaustible stream of new buyers.

For 2015 they’ll have even more temptation to try and resist, as the firm adds an X to the model designation.

Blending the brilliance

This isn’t just a bit of paint and a new decal, the headline change for the RX is the junking of the old tail unit, to be replaced by one from the Daytona 675R. It’s such an obvious mod that you have to wonder why they didn’t do it earlier.

The sleeker new silhouette is accentuated by the new Matt Silver paint and deep Diablo Red colouring of the lightweight race inspired wheels. Triumph’s accessory seat cowl, belly pan and fly screen are standard fitment, and complete the aesthetic overhaul.

The heart RX remains Triumph’s signature 675cc triple, a 12-valve unit derived from the Daytona sportsbike, which has been mildly retuned to deliver a punchy 105bhp and 50lbft of torque. There’s still nothing wrong with the motor, and being wisely conscious of that Triumph have left it well alone for 2015.

The new Street Triple RX will be available in dealerships from January 2015. Prices are yet to be confirmed, but we would expect only an incremental price increase over the existing R model’s £8149.

Engine

Triumph have not messed with the existing Street Triple R unit, meaning a 105bhp 675cc inline-triple, which is more than capable of tempting you and the RX into plenty of mischief.

Chassis

The front end of the bike is unchanged, while the rear subframe and seat unit are stolen directly from the Daytona 675R, giving the RX a sharper and sleeker rear end.

Electronics

The only new addition to the RX is the provision of the accessory quickshifter as standard fitment – making it even easier to get through to sixth on the back wheel.

Brakes

The R’s Nissin radial 4-piston calipers carry over to the RX, also with the switchable ABS system – all biting on to a pair of 310mm floating discs.

ORIGINAL STORY

If the decal on the side panel is to be believed, this is the new Triumph Street Triple RX, which MCN expects to be unveiled at the Intermot show in Cologne, Germany, tomorrow.

Spied undergoing a test at Cadwell Park in Lincolnshire two week’s ago, the model is clearly an interim update or special edition, rather than a new version of the massively popular triple.

Already a sales success for Triumph, the Street Triple has featured in the UK’s top ten best sellers consistently since its launch in 2007, and subsequent 2013 update.

This new version will only help it stay there, with its aggressive R styling, and the addition of a new subframe and tail unit, seemingly directly lifted from the Daytona 675.

Fitted with a flush-mounted cowl, it almost looks like a single seat unit, but the rear pegs reveal that there is a pillion perch hidden beneath.

Also visibly different is the colour of the Nissin radial brake calipers, while the units themselves appear to be identical to the existing Street Triple R’s.

- Published in Motorcycle Review

2015 New BMW S1000RR

2015 New BMW S1000RR, BMW’s superbike rivals must be wondering just what they have to do to keep up as the German firm reveals a completely new, lighter, more powerful and even more advanced version of the S1000RR; a bike that already dominates the class.

The 2015 S1000RR is the first completely new version of the bike since the original appeared in 2009; the 2012 overhaul being merely a bit of a polish up in comparison and it has distilled five years of racing and road bike experience to bring these changes to the new bike.

Nobody ever stepped off an S1000RR yearning for more power or less weight; but now they have both in the form of 199bhp at a searing 13,500rpm and a belting 83.3lbft torque, while the weight has dropped (even with all of the electronics and ABS system fitted) from 209kg to 204kg fully wet.

At the heart of the claimed 199bhp are changes including a newly-engineered cylinderhead, a new intake camshaft and lighter intake valves.

The airbox has been changed for a larger capacity and shorter intake lengths, while the all-new exhaust system ditches the front underbelly silencer to contribute to a 3kg weight loss. A lighter battery sheds another kilo from the total, too.

The frame changes are also comprehensive. The twin-spar aluminium alloy frame is both stiffer and lighter and gets new geometry with new steering head angle, wheelbase and a new swingarm pivot point.

The new S1000RR can also be specified with an updated version of the semi-active BMW Dynamic Damping Control (DDC) suspension system.

In terms of the electronics, BMW have fitted three standard modes of Rain, Sport and Race. They can be supplemented by the Pro riding mode option to give a further two, track orientated modes of Slick and User. Pro riding mode also offers launch control and a programmable pitlane speed limiter.

There’s also include a quickshifter for faster gearchanges both up and down the ‘box. The traction control has been recalibrated to work with the ABS and uses lean angle sensors to further improve the safety systems.

The S1000RR even gets optional cruise control and heated grips, along with a new LCD dashboard.

New S1000RR electronics

The BMW S1000RR set the standard for the superbike class when it was launched in 2009, but the challenge from the Ducati 1199 Panigale and Aprilia RSV4 has been hard fought. BMW are aiming to take the top step again with the 2015 S1000RR, which gets a host of new electronic rider aids.

Standard fit electronics include the three riding modes of Rain, Sport and Race as well as Automatic Stability Control (ASC) with a lean angle sensor. Add the Pro riding mode as an option and you get Slick and User modes along with Dynamic Traction Control (DTC), which adds the banking sensor and seven stages of traction control intervention.

The different riding modes modify engine power and torque, traction control and suspension set-up and ensure the ABS system is matched in the best way for the conditions. The optional User mode means the rider can tailor all of the different electronic settings to their own tastes.

Engine

Significant reworking of the 999cc engine has resulted in a 6bhp boost at peak, thanks to new intake cams, lighter valves, a new airbox and an all-new exhaust system – which also sheds 3kg.

Styling

The asymmetrical face of the RR has been reversed for 2015, while the whole package has been lightened and sharpened.

Electronics

A raft of features have trickled down from the HP4, and the new bike gets semi-active suspension, second generation traction control and quickshifter, and new riding modes.

Chassis

The biggest change to the new frame completely revised back section, adding more flex around the swingarm pivot to improve drive, mechanical grip and feedback.

ORIGINAL STORY

BMW have confirmed that they will release three new models at tomorrow’s Intermot show in Cologne, Germany.

Amongst the three is expected to be an all-new S1000RR, boasting new chassis, new bodywork, heavily revised electronics and strong rumours the engine has undergone the same level of development.

Not only will the new bike represent a serious increase in performance over the current model, it will also eclipse the spec of the firm’s flagship HP4, which will cease to be a part of the model line-up in 2015.

More power, more control

The new RR has still not been seen completely without any disguise, but with several very clear spy shots to work with, MCN commissioned this digital rendering (red and white S1000RR) to show all the design elements of the new bike.

Tomorrow we’ll see how close we are to the real deal, but this is as close as we can get to a photograph of the finished bike.

What can’t be seen in the spy shots is the rumoured engine work, which our European factory source suggests has been significant.

The net result is expected to be a hike of ‘five or six’ bhp at peak compared to the out-going model, meaning that the new RR will boast an output nudging 200bhp in standard tune.

While the crankcases look to be near-identical between the existing bike and the test mules, it’s thought that all the development has gone into the cylinder heads to achieve the power boost, in conjunction with a complete new exhaust system.

Power is nothing without control though, and BMW is continuing to use the S1000RR to showcase its technological prowess.

With the HP4 being discontinued for 2015, the RR is expected to benefit from everything that model had to offer, including the ‘cornering ABS’ which became available on the HP4 just a few months ago.

The system, developed by Bosch and also used by KTM on the 1190 Adventure, enables the rider to brake heavily mid-corner without tucking the front, or causing the bike to stand up.

This system will be linked to the RR’s rider modes and the HP4’s semi-active suspension (dynamic suspension system DDC), which is also expected to become standard fitment.

With chassis mods aimed at delivering more flex around the swingarm pivot for greater feel and connection between the back tyre and the tarmac, and the increased control offered by the suspension and electronic improvements, the RR is certain to widen the existing gulf from its competitors.

Expected changes

Chassis

The RR appears to have a new frame, and the clearest indication is around the rear section. The expectation is that more flex has been dialled in to increase connection

and drive.

Front cowl

The biggest change to the styling of the new RR can be found in its face. BMW appears to have reversed the asymmetrical headlamps compared to the 2010-14 models, while also adding a beak at the base of the cowl, which we have also seen in spy shots of the sport-touring version of the S1000, which we believe will

Electronics

What is impossible to identify from the spy shots is the level of electronic development on the RR., but we’d expect all the HP4’s functionality, and second generation traction control.

Exhaust

One of the first new details that emerged from the spy shots was a new exhaust system. The first image showed an aftermarket Akrapovic version with twin exits, while the most recent shot shows the new exhaust to be a more conventional unit, but more trapezoidal in shape.

Rearsets

The first two spy shots show the 2015 bike has new rearsets to go with the new main chassis. BMW’s Gear Shift Assistant (quickshifter) is visible in the shots, and we know the firm has been working on a new version – likely to be fitted to their flagship sportsbike.

Fairings

The spy shots show completely new bodywork on both sides, while maintaining the bike’s trademark asymmetry. BMW is clearly keen for this new model to look like an evolution, not revolution, building on the existing bike’s popularity, but maybe missing the chance to appeal to a new pool of buyers.

Brakes & Suspension

The 2015 bike is expected to get the new version of Bosch’s cornering ABS, which was made available on the HP4 earlier this year.

Dubbed ABS Pro by BMW, it will be standard fit on the new RR, and will communicate with semi-active electronic suspension, and multiple rider modes, including a new rider-set mode.

- Published in Motorcycle Review

Kawasaki’s new Ninja H2R

Kawasaki’s new Ninja H2R, It’s been a long time coming, but there’s no doubt whatsoever that Kawasaki’s new Ninja H2R has been worth the wait.

The sharp eyed will already have spotted the lack of headlamps, a numberplate hanger, indicators and mirrors (not to mention the fitment of slick Bridgestone V01 rubber), but don’t despair, the H2R is the track-only version of this incredible new Ninja – there’s a road bike in the wings, too. Called the Ninja H2, it will be unveiled at the Milan show in four week’s time.

The H2R you see here is the very pinnacle of what Kawasaki can do. The development concept was ‘to offer the kind of acceleration no rider had experienced before’, and with 296bhp available at your right wrist, it’ll certainly deliver that for the first time from a production bike.

While Kawasaki hasn’t given any indication of the bike’s acceleration capability or top speed, we believe this track-only unrestricted version of their new flagship could easily force its way through the air at well over 200mph.

At the heart of this all-new bike is a supercharged 998cc inline-four capable of developing 50% more power than its next nearest superbike competitor, BMW’s new 199bhp S1000RR (see over).

This intense power output could easily upset the dynamic performance of a normal superbike, so Kawasaki have drawn on all their different divisions to ensure that the chassis and aerodynamics are capable of coping with the power output, and resultant high speeds.

Using the Ninja name was an obvious choice, it’s a Kawasaki sportsbike after all, but the decision to use the H2 name shows how much reverence the firm has for its epoch-making 2-stroke Mach IV 750 triple, which was known as the H2.

In its day it delivered acceleration like no other, and with that being the goal for the H2R, it became an obvious choice. It also led to most of the world’s media claiming the new supercharged Ninja had to be a 750, also citing the other H2 – the ZXR750 H2 – but MCN has always maintained the new bike would be a litre class machine.

As well as carrying the Ninja moniker, Kawasaki have also graced the new H2R with their ‘River Mark’, a rarely used piece of branding which dates back to the 1870s, and reserved by the company for products they consider to be of particular historical significance.

Bespoke supercharger

The supercharger has been developed completely in-house with assistance from other the Gas Turbine & Machinery Company, Aerospace Company, and the Corporate Technology Division, all parts of Kawasaki Heavy Industries (KHI).

While the supercharger itself is entirely conventional, optimising it for use on a motorcycle meant that in-house development was essential to achieve the maximum power and acceleration characteristics the engineers wanted to offer.

That trellis frame

While everyone knew the new H2R was going to be supercharged, the trellis frame was far more of a surprise.

Developed using the latest analysis modelling technology, it has been designed to balance the huge power output of the motor, with enough flex to ensure the stability, mechanical grip and feedback needed for high-speed riding.

The primary objective was stability at ultra-high speeds, which usually means a long wheelbase, but Kawasaki didn’t want to sacrifice corning performance, so it had to be compact. The firm then looked to the aerodynamics to boost the H2R’s high-speed stability.

Slippery operator

As speed increases, wind resistance increases exponentially, so Kawasaki needed to make the H2R as slippery as possible, meaning that aerodynamics would play a crucial role in the bike’s top speed and stability.

With all but 300bhp on tap there’s clearly no deficit in the engine output, so the design team enlisted its Aerospace Company to help develop the dramatic sculpted bodywork to let it cut through the air.

The fairing design also maximises cooling performance and heat dissipation, helping the 998cc supercharged engine to operate in its ideal temperature range, while the Ram Air duct is ideally positioned to direct airflow to the supercharger.

Intense-Force Design & Craftsmanship

Kawasaki say that the styling concept for the Ninja H2R was defined by a three-word label: ‘Intense Force Design.’

This is the firm’s halo product, and every element is Kawasaki at its very best, from the engine and aerodynamic development, through to the mirror-finish black chrome paint specially developed for this model

Kawasaki confidently states that it’s the best bike they have ever built. So how much will all this cost you? Kawasaki won’t say yet, but expect this track-only model to be up there with Ducati’s Superleggera, while the road-going H2 is more likely to be around £20,000.

Bodywork

The carbon bodywork was designed with the assistance of the firm’s aerospace division to ensure optimum aerodynamic stability. The black chrome paint was developed specifically for the H2R to help reduce drag.

Supercharger

Designed completely in-house at KHI, this is no parts-bin bolt-on. Conventional litre-class sportsbikes can currently develop up to around 215bhp reliably, the H2R will be topping out at almost 300bhp – while the H2 road version is expected to be around 80bhp less.

Chassis

A trellis frame? On a Japanese superbike? It was certainly a surprise, but it’s the best packaging solution for the engine and chassis components, the ducting needed to the supercharger, and providing the blend of strength and flexibility needed.

Electronics

Kawasaki have given no indication of the electronics package fitted to the H2R, but there is a clearly visible quickshifter fitted to the selector arm, and its size suggests this will be for both upshifts and downshifts.

There is also a KISS sticker on the front fender, suggesting the firm’s in-house traction control system is present, and the steering damper clearly has electronic control. There’s no visual hint of the suspension being semi-active or electronic.

The Facts – Ninja H2R

Engine Type: Supercharged liquid-cooled inline-four

Displacement: 998cc

Supercharger Type: Centrifugal, scroll-type

Maximum Power: 296bhp

Frame Type: Trellis, high-tensile steel

Tyres: F: 120/600R17 Bridgestone V01 slick R: 190/650R17 Bridgestone V01 slick

ORIGINAL STORY

Kawasaki’s all-new supercharged Ninja H2 is now less than 24-hours away from being unveiled at the Intermot show in Cologne, Germany.

With MCN at the forefront of breaking news about the project since patents first started to be filed in 2011, the latest information leaking from Kawasaki suggests this bike is going to be a radical departure from their current range; a high-specification, super performance bike that will sit at the top of the range as a very distinct halo offering, likely to cost in excess of £20,000.

This is not a replacement for the ZX-10R, and insiders suggest this is not a replacement for the ZZR1400, either.

Way back in 2011 MCN revealed that Kawasaki had filed a host of new patents, all relating to a new supercharged motorcycle. From the outset it was clear that this was to be a high-performance, four-cylinder machine with a single supercharger mounted directly behind the engine.

Despite the lack of official information about the bike, one key statement to its intentions is hidden in the source data of the www.ninja-h2.com teaser website set up to plug the bike before its September 30 launch.

Titled ‘description’ it says: “The Ninja H2 was not designed with meeting regulations as a primary concern. Kawasaki’s latest flagship is the result of a pure exercise in pushing the limits of motorcycle technology with the goal of creating the ideal road sportsbike.”

The reference to regulations is clearly talking about racing rules rather than road-going regulations, which the bike will still have to meet if it’s to be the ‘ideal road sportsbike’.

Kawasaki’s decision to make the H2 a pure road bike promises to be the key to its abilities. Our information suggests that the engine will, as shown in some of the patents, be derived from the ZX-10R, keeping that bike’s 998cc capacity.

A sound clip of the bike revving through the gears on Kawasaki’s teaser website initially appears to be higher-pitched than you might expect, but an acoustic analysis of the noise shows that it’s revving to around 12,000rpm – which is what you’d expect from a 1000cc motor.

What about the rest of the bike? Although the most recent patents, surprisingly, show a tubular chassis design, we’re expecting the final version to be similar to the ZX-10R’s beam frame. But this is a high-end bike so we also expect top-quality suspension and electronics.

More than one of the patent images filed by Kawasaki has shown the bike with a single-sided swingarm – not something the firm is known for, but a styling element that’s become synonymous with high-end machines ever since it was adopted by the Honda NR750 and NC30, as well as decades of Ducatis.

This is unlikely to be a flash-in-the-pan for Kawasaki. At the same time as it filed applications for the trademark ‘Ninja H2’ it also filed ‘Ninja R2’ – presumably a derivative of the same bike, and possibly a more affordable mass-market follow-up?

The firm has also registered the name Ninja H2R, suggesting that tomorrow’s release could be a full-on track-only special edition of the H2, likely to benefit from extremely high-end components and materials, and able to fully exploit the new supercharger’s upper limits, meaning a output likely to be approaching 300bhp.

Get used to it

Official power figures have yet to be released, but we wouldn’t expect less than 250bhp – meaning the H2’s tailpiece, disappearing off into the distance, will be a familiar sight for most of us!

Sound’s strange

The engine note you can hear on the H2 teaser website has been acoustically analysed as revving at 12,000rpm, consistent with a 998cc engine. The unconventional sound will be down to the supercharger and the lack of traditional airbox.

Top spec components

Sitting as Kawasaki’s flagship sportsbike, the H2 will no doubt be dripping with high-spec suspension and chassis components, making it worthy of its £20,000 plus price tag.

Familiar face

The H2’s ‘face’ is likely to be dictated by Kawasaki’s decision on the air intake design. Recent patents show a set-up with a single intake on the left side but there are also patents that show symmetrical intakes, too.

How a supercharger works

Any petrol engine’s power is basically governed by how much fuel it can burn. And to burn fuel, it needs air to mix it with. There are three basic ways to get more air into an engine: increase its capacity, increase revs, or compress the air before putting it into the cylinder – and that’s where superchargers and turbos come in.

There are several types of supercharger, but all the Kawasaki designs we’ve seen so far have used centrifugal superchargers. They use a finned disc called an impeller, which is spun at around 100,000rpm to suck the air in through a central hole in the compressor housing, which is the part shaped like a snail’s shell.

It’s basically the same as the compressor side of a turbocharger, but instead of the impeller being driven by exhaust gas, a supercharger’s is driven from the engine’s crankshaft, via gearing to massively increase its speed.

Because compressing air makes its temperature rise, most modern supercharged engines also have intercoolers to bring its temperature back down. Intake air that’s too hot is inefficient and potentially dangerous to the engine.

Kawasaki’s designs so far have shown an air-to-water intercooler, where the intake heat is removed by passing it over water-filled tubes, with that water pumped around its own cooling system to an extra radiator to cool it down again.

- Published in Motorcycles

MV Agusta set for BSB with Tsingtao Kawasaki

MV Agusta set for BSB with Tsingtao Kawasaki, MV Agusta will return to the MCE British Superbike paddock for 2015, with national Superstock 1000 championship leaders Tsingtao Hampshire Motorcycles making the switch from Kawasaki, for not only superbike but also supersport.

Team owner Dave Tyson said: “We wanted to start planning for the 2015 season at the earliest opportunity and we have been looking at the different markets and have worked in the past with MVs. We visited the factory and had a positive meeting with them and we have developed a new partnership which also includes converting our showroom into MV’s flagship store for the UK.

“We have the bikes and we have already stripped down the F3 and have started work on it. The advantage we do have is that the MV team in Italy are sharing the information so we can work together on the development. The MV is a proven package in the World Supersport Championship and is built as a race bike so has huge potential. Nick [Morgan] will continue as our technical partner at MSS Performance and they will work closely with the factory to develop the engines.

Team boss Tyson’s Hampshire Motorcycles will be having a special event this weekend to celebrate their new MV Agusta dealer status at the dealership in Waterlooville, with everyone welcome.

source http://www.motorcyclenews.com/mcn/sport/sportresults/british-superbikes/2014/september/MV-Agusta-set-for-BSB-with-Tsingtao-Kawasaki

- Published in Motorcycles