Fullsix Carbon Fibre – CDT Carbon Fibre Group – Conquest Carbon

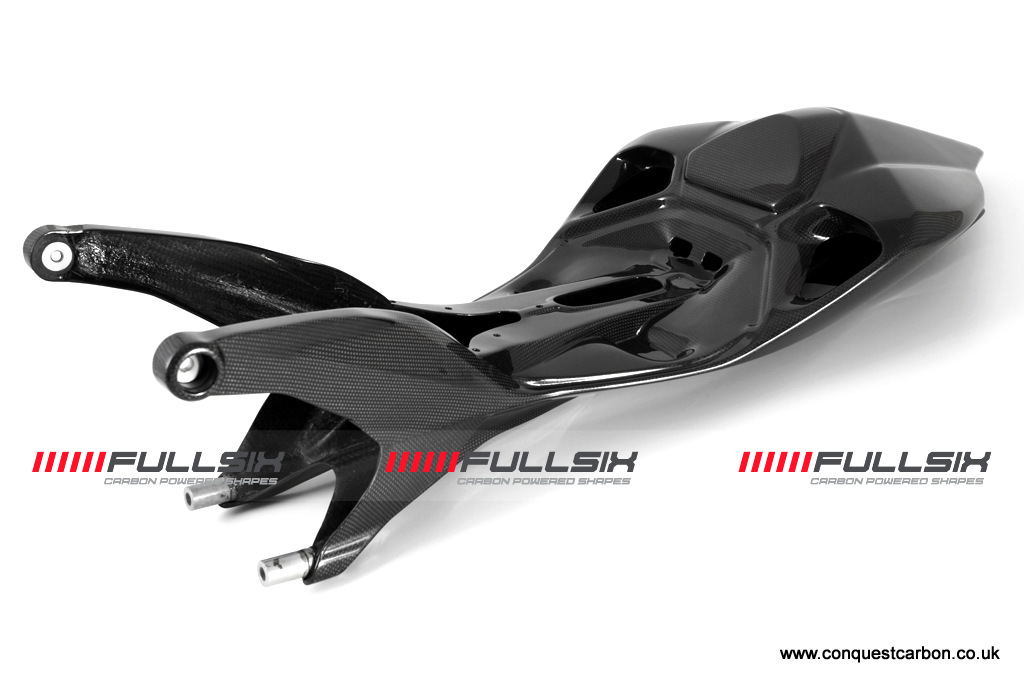

Fullsix Carbon Fibre – CDT Carbon Fibre Group – Conquest Carbon now dealers for their stunning carbon creations.

Click here to view their parts

CDT Group

Since 2008, CDT Group has been one of the world leaders in the production of high quality carbon fiber parts, both as an original equipment manufacturer (OEM) and as an aftermarket manufacturer. We are among the world’s leading brands in the automotive and motorcycle industry and we are passionate about developing the best products. Our young and highly qualified staff is the driving force behind our commitment to offer you only the most innovative products. We guarantee only the best for your motorcycle: a perfect look, precise fitting, outstanding performance and supreme quality. Our passionate pursuit of perfect carbon fiber parts has consolidated our position in the world market.

The FullSix brand was designed with the desire to achieve perfection. Through the use of autoclave technology and new composites we guarantee our customers only the best carbon fiber products. Our innovative manufacturing processes make us the only company in the market which is able to ensure flawless production. The quality of our manufacturing processes is reflected in our latest cutting-edge product from Slovenia and we have achieved something no one thought possible: a perfect one piece carbon fuel tank.

Vision

Our vision is to become the world leader in the production of the highest quality class of carbon fiber parts for motorcycles. We aim to achieve our goal step-by-step, focusing on technological innovation, hard work and a constant pursuit of perfection. From Slovenia, the home of many world recognized brands in the motorcycle industry, we are introducing the highest quality range of carbon fiber products to the world market. Our innovations in the field of manufacturing and production, such as our proprietary Autoclave Composite Monocoque (ACM) technology, make us a pioneer in the industry.

Fullsix products

FullSix carbon fiber parts guarantee an excellent appearance and perfect manufacturing. By using state-of-the-art technology and an innovative blend of materials, we assure you that our parts will upgrade your motorcycle both visually and in terms of performance. We have paid particular attention to ensuring that all carbon fiber parts are UV protected through the use of special lacquers, as we know that our customers desire eternal beauty and perfection.

We accept no compromises, we take no shortcuts. Careful attention is paid to details to achieve that final sparkle that is the difference between good and supreme products. Good looks are not all we are proud of. Using state-of-the-art technological solutions, we ensure that each part is completely compatible with your motorcycle. All parts and accessories that are needed to install your Fullsix product are included, so you can install every piece yourself.

The uniqueness of our products is not just an advertising slogan, but the underlying philosophy of our company itself. Since we believe in providing only the best for your motorcycle, we have developed a unique production monitoring system that ensures that all Fullsix products are manufactured according to the latest protocols and “best-in-the-industry” standards. Through the use of unique barcode technology, CDT Group is teh only company in the market that is capable of tracing products through the entire manufacturing process, resulting in products that you completely trust.

Fullsix stands for perfect looks, precise fitting, outstanding performance and supreme quality.

CDT Group is known worldwide for its quality parts which are made from only the best materials and technology. We use only five star materials, shaping them into real pieces of art with our precisely engineered autoclave technology.

Our products stand out in terms of quality, as every step of the production process can be traced and monitored using barcode technology. This enables the company to have complete control over the production of its products, so that each and every product which carries the FullSix logo has consistency and quality that can be fully trusted.

All steps of of the production process are manufactured to perfection: from the cutting of fabric to the final paint job.

Our collaboration with world renowned research institutes, such as the Jožef Stefan Institute, has placed us amongst the most innovative enterprises in the field of composite manufacturing. With scientific precision we carefully determine the properties of the materials which will enhance the visual appearance and performance of your motorcycle.

This enables us to guarantee flawless production processes and the top quality attributes expected of FullSix products.

ACM Technology

CDT Group is the inventor of Autoclave Composite Monocoque (ACM) technology and is the only company in the world that is able to produce a high decorative finish complex-shaped closed-body monocoque out of a single carbon fiber-based unit (e.g. a one-piece fuel tank for motorcycles). This technology is directly applicable for fabrication of various one-step closed-body monocoques, where no cutting, trimming and bonding is required. In contrast to conventional bonding, ACM technology provides monocoques with supreme mechanical strength, chemical resistance and a flawless finish.

Monocoque fuel tank

Despite claims that it was impossible, we have successfully utilised our innovative ACM technology in manufacturing a flawless hollow carbon fiber part. We have developed a tank that solves the problems that plagued carbon tanks in the past – meaning they were only bought by the bravest of motorcyclists. Rest-assured, today you can forget the difficulties associated with the tanks made of two parts. You no longer need to be concerned about leaking seams which made carbon fiber fuel tanks the most dangerous part of a motorcycle.

Our groundbreaking ACM technology represents a novelty in technology and production – a special innovative technological process developed by CDT Group for manufacturing hollow pieces without joints and adhesives.

The CDT Group’s R&D team is constantly monitoring and improving the technological procedures used for the production of high-tech carbon-fiber composite products. Our R&D is orientated towards functionalization of high-quality carbon-fiber composite parts and launching of novel products exhibiting state-of-the-art properties. Current major R&D projects are focused in the following strategic areas:

– The development of Autoclave Composite Monocoque (ACM) technology.

Our ACM technology represents a breakthrough in technology and production – a special innovative technological process developed by CDT Group for manufacturing every hollow piece without joints and adhesives.

– Utilizing nanotechnology to produce superior parts.

Through the use of nanotechnology, CDT Group is able to produce carbon fiber parts that have enhanced properties that offer superior value compared to competing products (e.g. scratch resistant clear coating).

– Development of photovoltaic carbon-fiber composite components for lightweight solar-powered electric motorcycles.

The major advantages of electric motorcycles in contrast to vehicles with conventional combustion engines are extremely low noise pollution and zero-carbon emissions. Electric motorcycles have linear torque curves which are a major advantage in relation to conventional engines. Acceleration is vibration free, resulting in better track traction and lean orientation. When a motorcycle is designed as a self-sustaining energy system (e.g. solar-powered), the weight of these electrically driven vehicles need to be minimized. Here, carbon-fiber composite components are preferred due to their high strength-to-weight ratio. Our goal is to develop a platform composed of flexible photovoltaic cells integrated with carbon-fiber composite modules with high-aesthetic standards which are able to convert light into electricity. This technology can be adapted to become applicable in various low-weight mobile applications where light-electricity conversion is utilized.