SC Project Exhausts UK Dealer Receive A Quote Today

SC Project Exhausts UK Dealer Receive A Quote Today

Conquest Racing Ltd is proud to be the longest-serving official UK dealer for SC Project Exhausts.

SC-Project is the leading company in the development, design, and production of exhaust systems for both racing and road motorcycles.

Established in 2006, SC-Project’s mission has always been to showcase the excellence of “Made in Italy” products worldwide. Our products are distinguished by the use of top-quality materials, advanced technologies, innovative design, and continuous research.

Our headquarters are in Cassinetta di Lugagnano, in the Milan metropolitan area, and are close to Malpensa Airport. The facility comprises four adjacent buildings (three interconnected) covering over 15,000 square meters, with 8,000 square meters of indoor space.

We employ more than 100 people, including engineers, technicians, administrators, and skilled workers.

SC-Project products are distributed globally.

- Published in Conquest Racing Parts

Bodis Exhaust Dealer UK

Bodis Exhaust Dealer UK

Welcome to Conquest Racing Ltd, we are proud UK dealers for Bodis motorcycle exhausts, view their range in our online store.

Bodis Exhaust UK

Bodis exhaust manufacture high-quality performance road and race exhausts with 30 years of experience in processing stainless steel and titanium. Development and construction of groundbreaking exhaust systems for motorcycle racing, plus an up-to-date range of aesthetic exhaust systems offering increased efficiency and optimized sound. That’s BODIS.

Development and manufacturing take place in Hungary, while Speer Racing Parts, based in Germany, is responsible for worldwide homologation and distribution.

Together we are an unbeatable team.

Motorcycles are our passion.

- Published in Conquest Racing Parts

Zard Exhaust UK Distributor & Dealer for Trade & Retail – Shop Now

Zard Exhaust UK Distributor & Dealer for Trade & Retail – Shop Now

Welcome to Conquest Racing Ltd, we are proud UK dealers & distributors for the Italian exhausts manufacturer Zard

From dream to reality

Thirty years of experience in the production of high-quality exhausts, a building with an area of 15,000mq, and a staff of over 100 people. From a story full of authentic passion, racing and a continuous desire to produce the best.

Zard develops innovative motorcycle exhausts characterized by our unique design.

Our R&D department, led by Valter Amistà, works in total synergy with the entire technical team to reach a cutting-edge and constantly evolving product.

“Our products aren’t imagined according to cold numbers,

we look for alternative creativity. Our product must have a strong identity.”

Cafè Racer Magazine, Aprile 2004

Each exhaust is developed on a motorbike. Craftsmanship and technology are the main features that characterized our artworks. The production is supported by the use of latest generation software, reverse engineering instruments, press, 2D and 3D laser, robot, bending machine, rolling press, and Dynamometer.

Every single step, from welding to assembly of semifinished works, is handmade using high-quality raw material. The result is a total Made in Italy product.

“The desire for new goals and new challenges is the engine of life, and like in any engine,

the exhaust is one of the most important components of it.

It isn’t a ferrous and static element, but it is an instrument that gives voice and soul to the motorbike.”

Kustom World, Maggio 2015

- Published in Conquest Racing Parts

Rotobox Carbon Fibre Bullet Wheels Official UK Dealer

Rotobox Carbon Fibre Bullet Wheels Official UK Dealer

Thank you for visiting our online store.

We are official UK dealers for the awesome and unique Rotobox carbon fibre wheel manufacturer.

Below is info about each wheel they manufacture, to shop for wheels for you bike click on the link below:

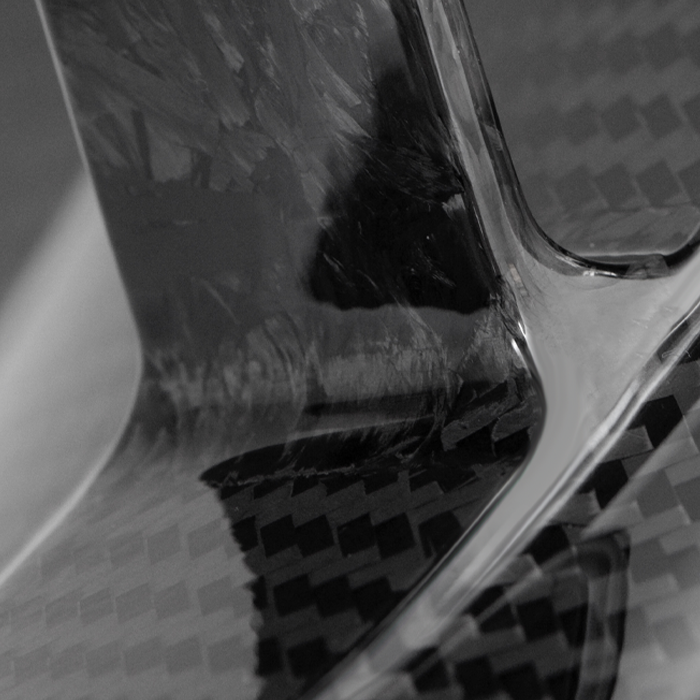

CARBON FIBRE FEVER

Low weight, high stiffness, great strength and eye-catching design are the obvious reasons for the continuing growth of carbon fibre used in the motorcycle industry. One of the most important parts to significantly improve a motorcycle’s overall performance – from handling, breaking to acceleration – are carbon fibre wheels. With the industries first 3 component composite (carbon-epoxy-steel) and its unique one-piece hollow carbon cast construction, Rotobox is redefining the quality and manufacturing standards of a whole industry. This puts us on the forefront of carbon fibre motorcycle wheel innovations.

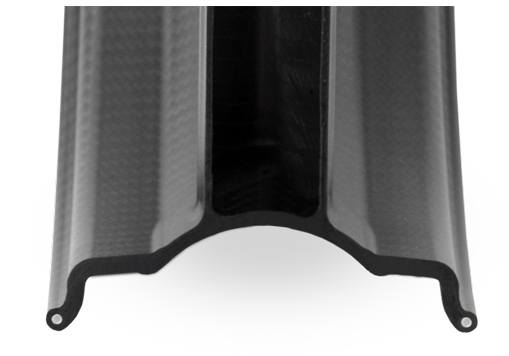

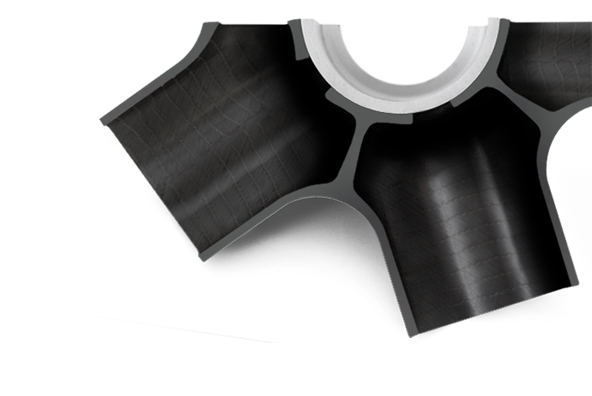

ONE-PIECE HOLLOW CARBON CAST

Rotobox is the first and still the only carbon fibre motorcycle wheel producer in the world to develop and use a unique 3 component composite – combining carbon, epoxy and steel. As the composite itself, the one-piece hollow carbon cast production process is a novelty as well. During production, several different types of CNC tailored carbon fabrics are hand placed into the negative forming mould of the high precision aluminium tool. For greater impact resistance a stainless 2,5 mm steel wire is added in each side of the rim. Next, the liquid epoxy resin is injected into the sealed and tempered tool under very high pressure. This process of producing the one-piece hollow carbon cast is an adaptation of the special high-pressure Resin Transfer Molding (RTM) technology. Ensuring the continuous quality, safety and accuracy of the production process.

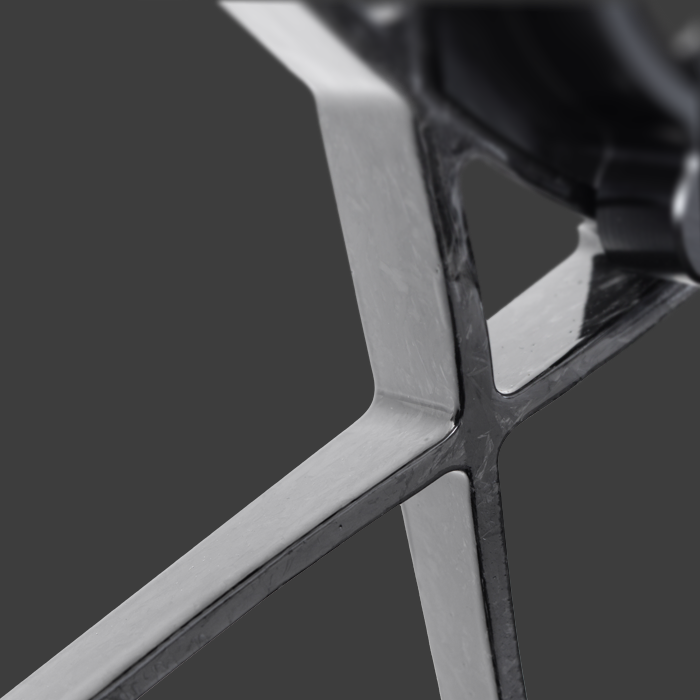

SOLID THIN SPOKES

To create solid thin spokes we use special carbon fibre yarn developed for military use. Because of the extreme mechanical properties of the fibres that we use (tensile strength 6000 MPa) and high-density forging process, the cross-section of spokes becomes small and compact.

CHOPPED CARBON FIBERS MEETS WOVEN FABRIC

Our unique technology enables combining chopped carbon fibres with woven fabric seamlessly in the one-piece monocoque.

THE CENTRE PARTS

The hubs are CNC machined from 7075 T6 aluminium alloy, anodized into optional colour and permanently assembled to the carbon rim. Designed specifically for each motorcycle model, the Rotobox wheels are a direct replacement of the OEM-wheels and are supplied with a cush drive, sprocket carrier, spacers and a choice of ceramic or steel bearings.

HIGH-PRESSURE CORE

The new technology achieves a high density of armature in the composite, extreme metric accuracy and a greater smoothness of the wheel surface. In addition – the wheel becomes watertight. Thanks to the High-Pressure Core Technology the structural rib is placed in the inner side between the spokes, with its mission to support the stress hot spot of the wheel. As a result the BOOST elegant spoke design brings greater stiffness and although the spokes are thinner the BOOST is stronger than ever – with a permissible static load of 280 kg on the rear and 180kg on the front wheel

RACETRACK INSPIRED DESIGN

The look of the Rotobox wheels is determined by the company’s philosophy to achieve the highest possible performance and safety with no compromises to popular design guidelines. To maximize the advantages of carbon fibre composite, and simultaneously reduce all known disadvantages, we let the experience and expertise of our professional testing team YART (Yamaha Austria Racing Team) flow into the wheel design. The outcome is a spoke, which meets the rim on a substantially large area.

TESTING LAB

RADIAL FATIGUE TEST

The test aims to confirm the durability of the rims and hubs. For this purpose, a drum is rotating the wheel at a constant velocity of 80 km/h while applying the radial load (FW: 340kg / RW: 560kg at min. 500.000 cycles).

TORSION FATIGUE TEST

The test aims to confirm the durability of the spokes and hubs. For this purpose, the wheel is fixed onto the support, while the torsional moment (FW: 442Nm / RW: 790Nm at min. 100.000 cycles) is repeatedly applied through the contact surface of the hub.

CORNERING FATIGUE TEST

The test aims to confirm the durability of rims and hubs. For this purpose the wheel is fixed to a rotary disc, that is able to provide a bending moment (FW: 217Nm / RW: 387Nm at min. 100.000 cycles) to the centre of the wheel while rotating with a constant velocity.

IMPACT TEST

The test aims to confirm the air attainability of the tires and strength of the rims, spokes and hubs. For this purpose, the striker weight (FW: 225kg / RW: 375kg) is dropped on the wheel from a height of 150 mm to apply the impact load.

RACERS KNOW, WHAT RACERS NEED.

How to make the lightest and strongest wheel on the world? That’s the question motorcycling racer, research & development engineer and Rotobox CEO Gregor Bizjak asked himself more than a decade ago. The answer was a revolutionary 3 component-carbon-epoxy-steel-composite and a newly developed production procedure, which paved the way for a new generation of high-performance motorcycle wheels by Rotobox.

THAT’S HOW WE ROLL

Since the very first day, Rotobox strives to take the performance of carbon fibre wheels to a new level. By continuously pushing the boundaries of creative engineering our products set industry standards for lightness, stiffness, design and premium quality. Whether on the track or on the road – the racing DNA of the Rotobox team is not only reflected in our wheels but can be felt with every meter driven. The feedback of our great costumers confirms, that we are turning the wheel the right way.

SIMPLY THE BEST

- Published in Conquest Racing Parts

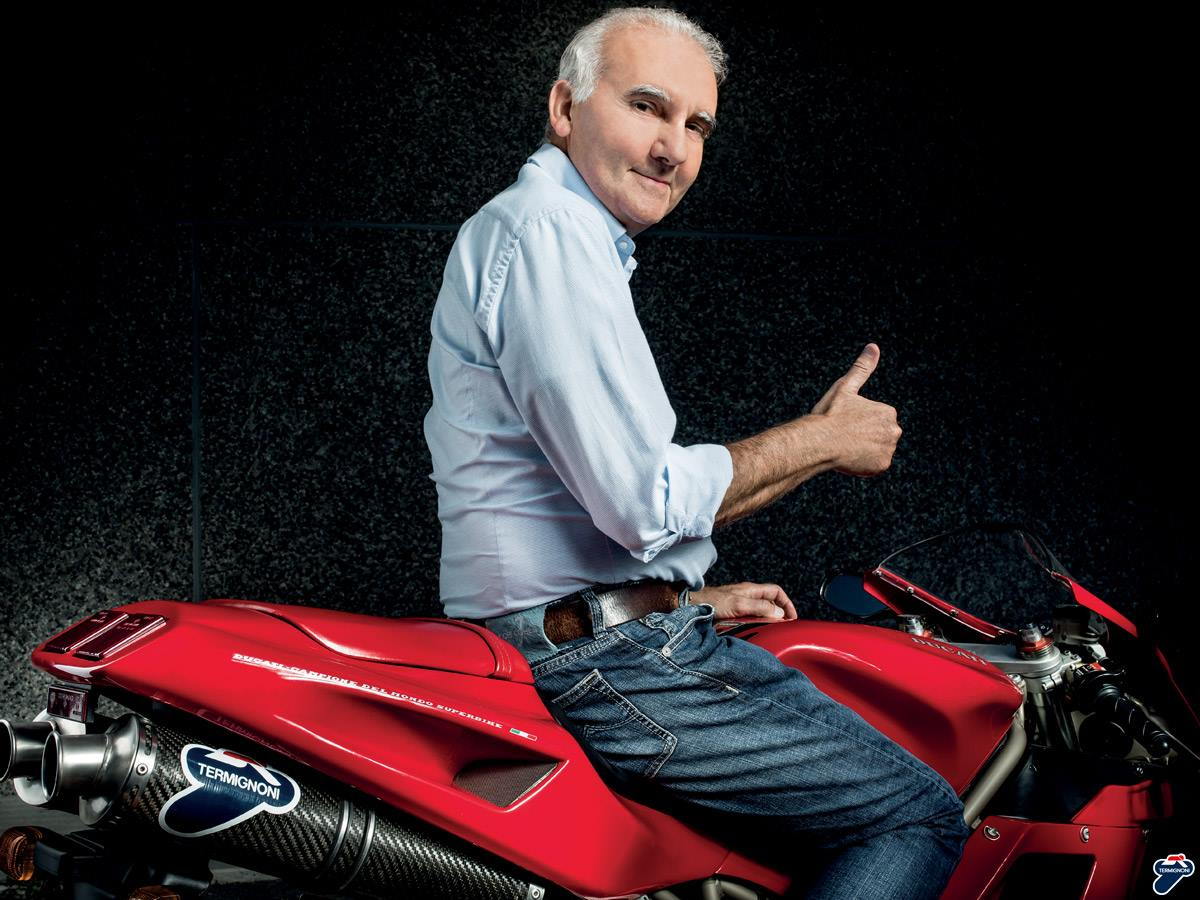

Termignoni Exhausts Dealer UK

Termignoni Exhausts Dealer UK

Founded in 1969 by Mr Luigi Termignoni, TERMIGNONI is a company which designs and creates motorbike exhaust systems for race and road use at the highest levels.

Our experience gained in these years on the race tracks has been transferred also to the aftermarket products giving high-level performances.

Our company’s object is to develop exhaust systems that always offers an increase in performance in terms of power or weight.

Termignoni Exhausts Dealer UK

Termignoni passion is motorcycles, our products & exhausts are the result of more than 45 years of experience.

We believe in sound and we want you to feel the soul of the motorcycle’s engine.

Our commitment is to create unique designed exhaust and provide the best performances.

Our main aim is to develop exhaust systems capable of giving increased performance in terms of power and weight reduction, the teams involved in competitions & racing, as well as the everyday motorcyclist.

Our R & D department designs and creates inhouse the racing facilities for the likes of MotoGP, Moto2 and SBK, this means that the knowledge and improvements acquired from racing facilities are also passed on to end-users.

Termignoni Exhausts Dealer UK

- Published in Conquest Racing Parts