Puig – Motorcycle Screens – Motorcycle Parts- UK Dealer

Puig – Motorcycle Screens – Motorcycle Parts- UK Dealer

Welcome to Conquest Racing Ltd authorised UK Puig dealer/distributor.

Puig is a family run business located in the Catalonian region of Spain. They specialise in the manufacturing of motorcycle performance parts inc screens, race screens, touring screens, auxiliary lights, mirrors, huggers, crash protection and so much more.

Click on the link below to view the Puig accessories we have available on our site.

Puig – Motorcycle Screens – Motorcycle Parts- UK Dealer

About Puig Motoplastics.

Puig brothers founded the company “Industrial Plástico Puig” in a 100 sq.m. garage in Granollers in 1964. They started manufacturing complete fairings in polyester fibre for Derbi and Vespa

The experience throughout these years is directly applied to each and every single product designed; for this reason, PUIG has been able to acquire the trust of many professional riders and motorcyclists that have used and are using our products.

Our commitment to plan, carry out, and distribute quality products, which are able to improve the OEM equipment of the motorcycle and motorcyclist on technology and safety performances, is achieved thanks to the synergy of the PUIG team whose values are always related to the best product development.

The technology is, in this industry, a must, and from the very beginning, PUIG has entrusted its future to it. On top of continued improvement on the quality product through technology integration, PUIG nowadays has a specialized department of design and development of new products, creating, adapting, and testing all new products that year by year are being included in our catalogue

With the incorporation of new technologies and new infrastructure year after year, PUIG guarantees to its customers the obtaining of high-quality products throughout its range. In addition, with the same objective of guaranteeing high-quality products, PUIG is certified with ISO 9001 and homologated by the prestigious T.Ü.V. German.

- Published in Conquest Racing Parts

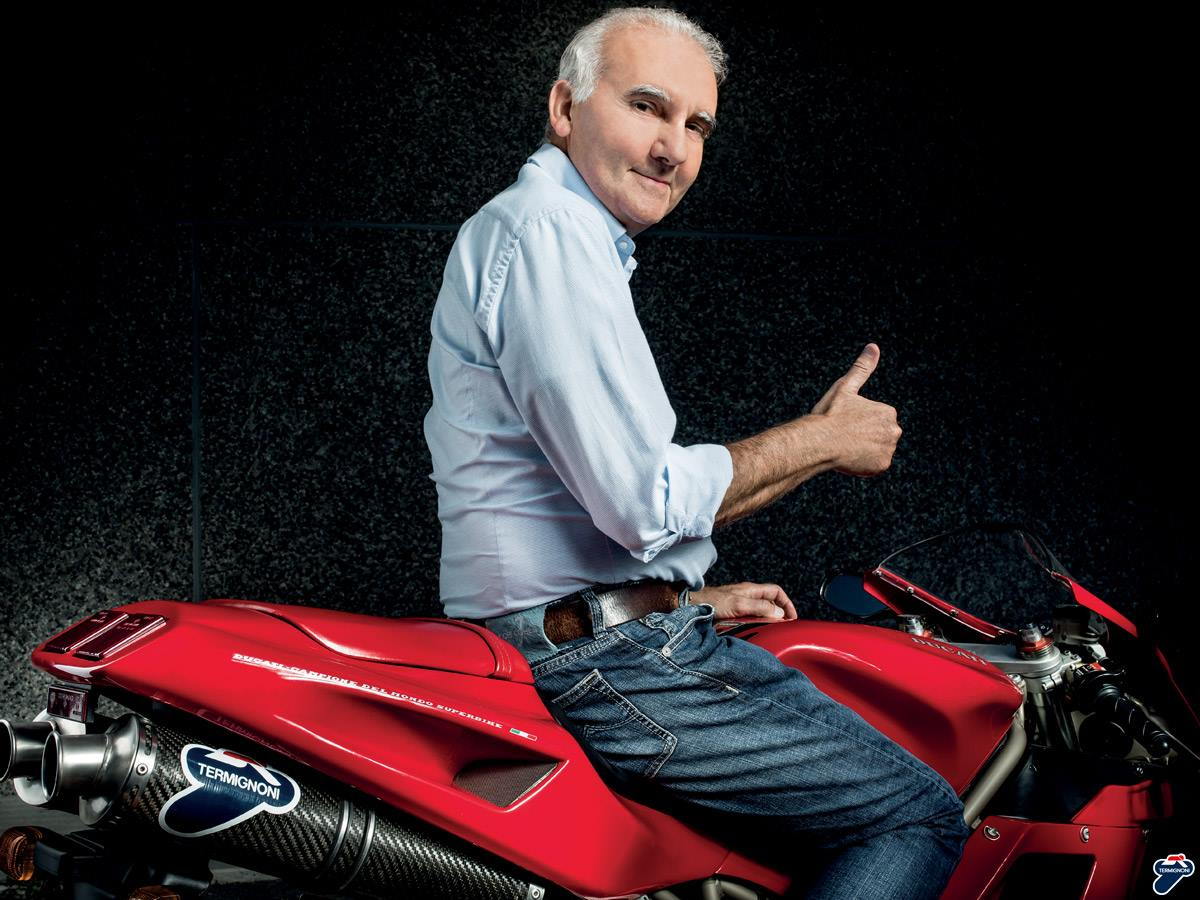

Termignoni Exhausts Dealer UK

Termignoni Exhausts Dealer UK

Founded in 1969 by Mr Luigi Termignoni, TERMIGNONI is a company which designs and creates motorbike exhaust systems for race and road use at the highest levels.

Our experience gained in these years on the race tracks has been transferred also to the aftermarket products giving high-level performances.

Our company’s object is to develop exhaust systems that always offers an increase in performance in terms of power or weight.

Termignoni Exhausts Dealer UK

Termignoni passion is motorcycles, our products & exhausts are the result of more than 45 years of experience.

We believe in sound and we want you to feel the soul of the motorcycle’s engine.

Our commitment is to create unique designed exhaust and provide the best performances.

Our main aim is to develop exhaust systems capable of giving increased performance in terms of power and weight reduction, the teams involved in competitions & racing, as well as the everyday motorcyclist.

Our R & D department designs and creates inhouse the racing facilities for the likes of MotoGP, Moto2 and SBK, this means that the knowledge and improvements acquired from racing facilities are also passed on to end-users.

Termignoni Exhausts Dealer UK

- Published in Conquest Racing Parts

CONQUEST RACING LTD

CONQUEST RACING LTD

Conquest Racing Ltd (AKA Conquest Carbon) was founded back in 2012 as a motorcycle clothing & accessories shop in Dorset south England UK. Our business has flourished ever since so inevitably we decided a website to sell the inventory was essential.

We realised that carbon fibre was a very popular product so we set out to find the best manufacturers to supply our customers. From the word go we have always strived to seek out and acquire the very best motorcycle performance parts that manufacturers in the motorcycle industry can provide, as we see it as our personal mission to be leaders in this vastly competitive marketplace. Never willing to sit still and relax on our laurels, we have moved on to supplying other high-performance motorcycle parts including CNC parts, race screens, crash protection & performance air filters up to and including performance exhausts for road and race use. To reflect this expansion of our company’s direction and the huge array of performance parts available for your motorcycles we have decided to change our name to what is now known as CONQUEST RACING LTD.

We would like to extend our deepest and heartfelt appreciation to all our valued customers who have helped our business become what it is today and we welcome the opportunities to continue to serve our existing customers and look forward to meeting and providing for new customers of Conquest Racing Ltd from now and into the bright future that beckons. We hope you will come and visit our online shop again to see what fantastic new products we will have available for your pride and joy.

Wishing you all happy and safe riding. From us all at Conquest Racing Ltd.

To see all our products for your bike please click on the SHOP NOW link below.

- Published in Conquest Racing Parts

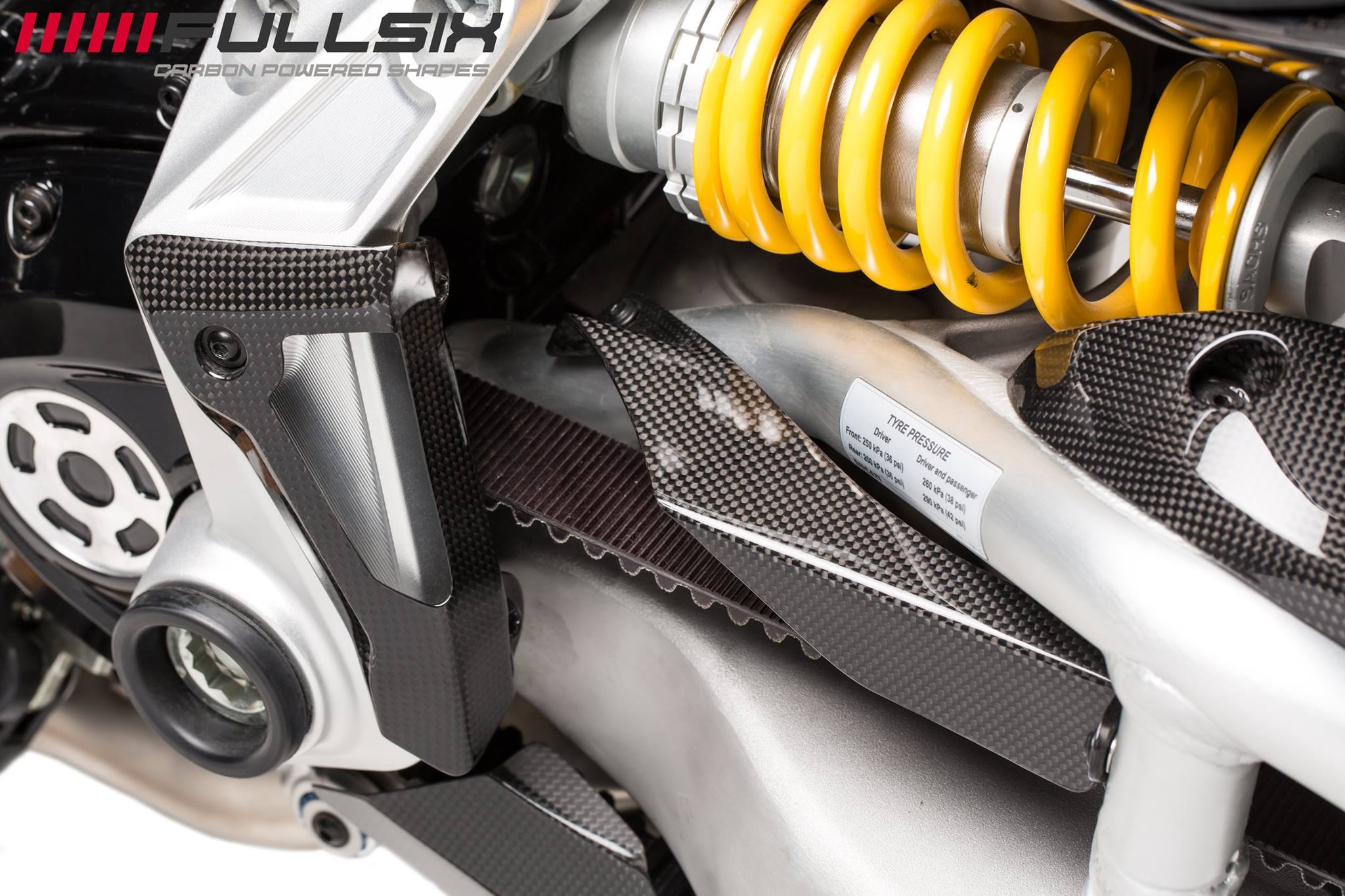

New Ducati Panigale V4 Carbon Fibre Parts By Fullsix Carbon

New Ducati Panigale V4 Carbon Fibre Parts By Fullsix Carbon

Now available to pre-order (delivery time 4-6 weeks) stunning carbon parts manufactured by Fullsix Carbon.

Available in gloss or satin/matte finish, identical weave to Ducati Performance carbon and made to the highest quality using the most sophisticated technology in the composite industry.

Be the first to have these stunning parts on your Panigale V4.

More parts to follow in the coming weeks, including carbon fibre fuel tanks, monocoque rear seat/subframe, full fairings, race fairings etc etc………

https://conquestracingltd.com/shop/pro…parts/fullsix-carbon-ducati-panigale-v4-road/

- Published in Conquest Racing Parts

Sprint Filter Air Filters UK Dealer

Sprint Filter Air Filters UK Dealer

Sprint Filter air filters are widely gaining in popularity in the world of racing. Many top teams have chosen them, with their better performing polyester filter, for winning the World Championships.

POLYESTER AIR FILTER: A WINNING TECHNOLOGY

On the one hand, air filters have to guarantee good air flow. On the other, they have to filter large particles so they don’t end up in the cylinders. The two operations are opposed to each other, and the best air filter is the one that optimises these two functions. Production motorbikes are normally fitted with paper filters, while the usual solution for sports filters was oil-‐soaked cotton. With its adoption of the polyester membrane filter, SPRINT FILTER has taken a huge leap forward, making all previous systems obsolete.

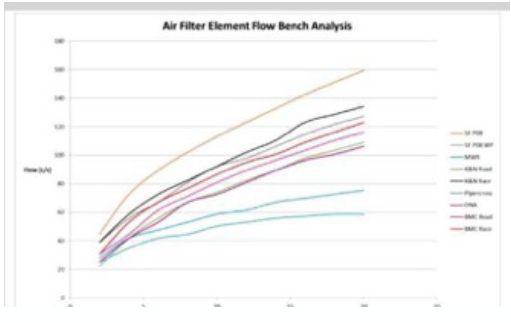

Leading brand air filters put to the test

STRUCTURE:

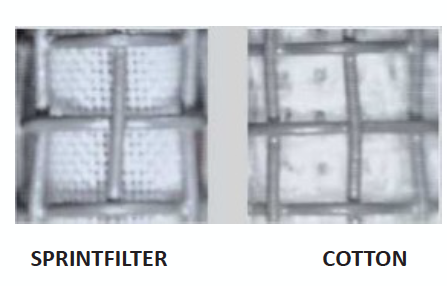

Polyester fabric is extremely permeable and solid and cannot be affected by folding during construction, by the difference in pressure during operation or by maintenance. On the other hand, the

cotton filter has a weft that depends on the overlapping and number of layers used. Moreover, it tends to lose its shape during these phases and, as a result, some zones will benefit from a high filtration value while others will filter poorly.

MAIN FEATURES:

• Constant filtration and air flow value over time.

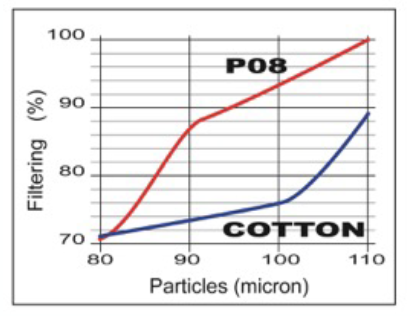

• In terms of efficiency, the P08 polyester filter retains 93.13% of 100 μ. particles as compared to the 76.42% that cotton retains .

• Construction of the support in just one material, to prevent unwanted separation of different materials.

STEEL MESH:

Another step forward has been taken for the P08 and P16 air filters, which once again distance themselves from the competition owing to the use of innovative technologies. After using the polyester filtering element, Sprint Filter is the first company in the world in this market to use steel mesh with epoxy varnish to support the membrane filter. The advantages? The strength of the wire allows a wider mesh to be woven, with the free surface increasing from 66% to 80%, which means the filter can be made with superior structural characteristics.

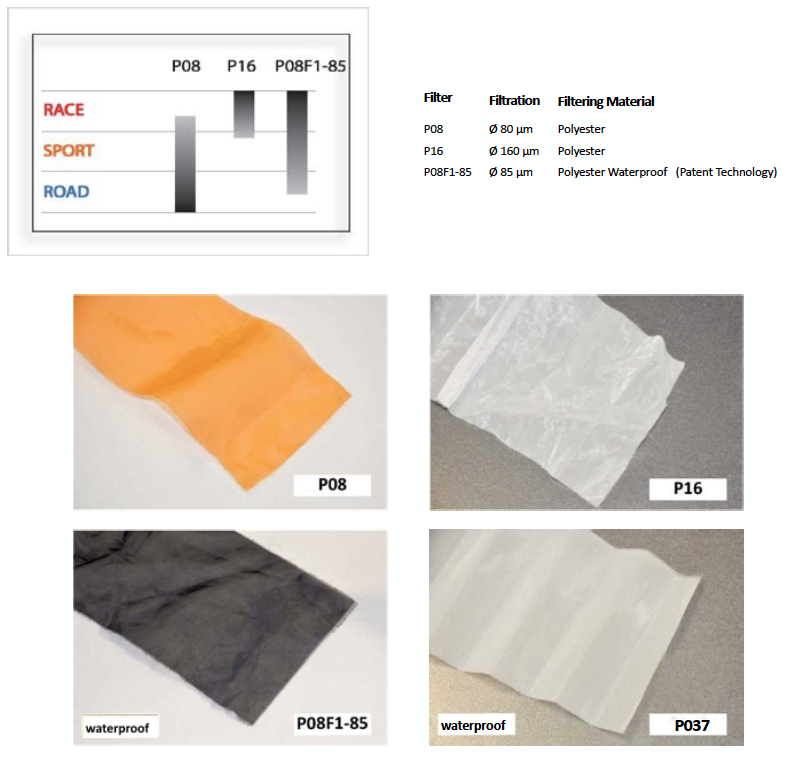

Using steel instead of a light alloy does not increase the weight. Not only is the mesh wider, but the diameter of the wire used is smaller than that of the past, and this more than compensates for the greater specific weight. Finally, even the look of the filters has now improved: less polyurethane seepage is noticed on the filtering map (orange for P08s, white for P16s and P037s, black for P08F1-‐85s) so it is better defined.“

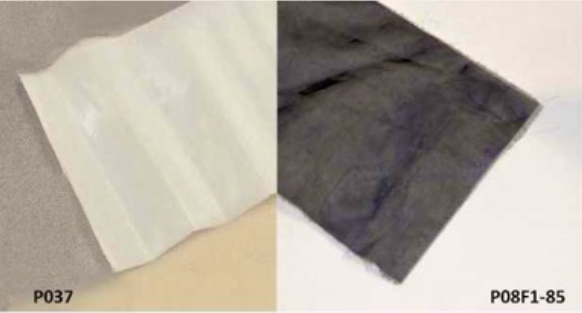

WATERPROOF” TISSUES:

Sprint Filter introduces the “waterproof” filter fabric on the P037 and P08F1-‐85 models (a Sprint Filter patent, meaning it is the only manufacturer in the world to produce waterproof air filters for internal combustion engines), making the product even more exclusive and suitable even for use in more demanding conditions.

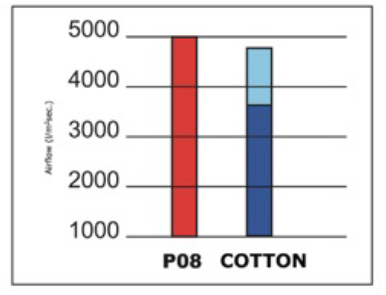

AIR FLOW:

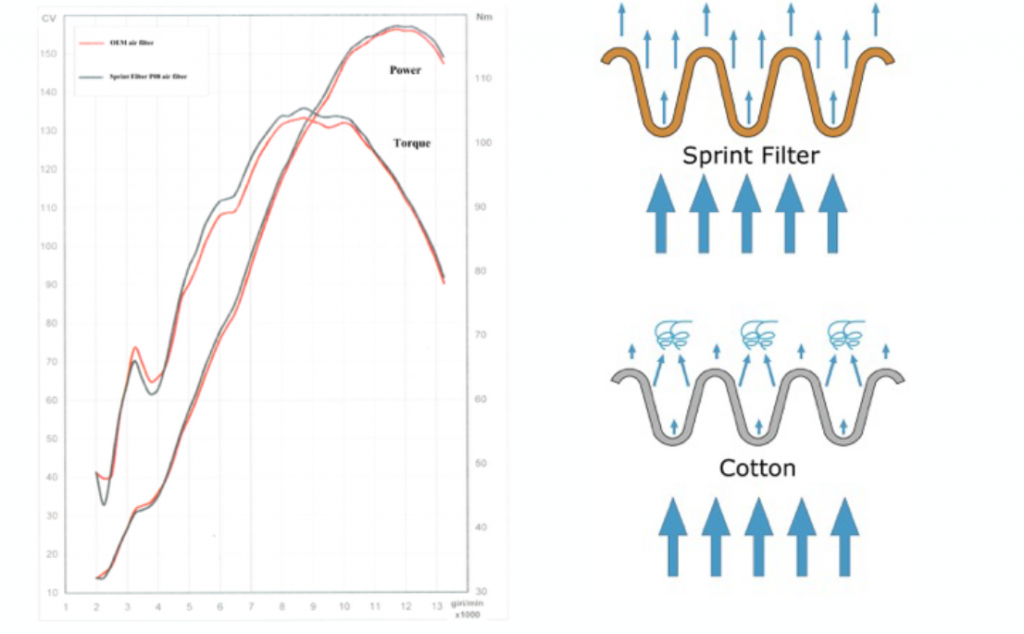

The polyester air filter guarantees a very high air flow that neither cotton filters (whose permeability depends on the number of layers used), nor OE paper filters can achieve. Remember the simple equation: more Air = more Power!

FILTRATION:

The construction precision of the polyester filter offers a filtration degree equal to that declared and is constant over time. The cotton filter, instead, has extremely variable openings, from just a few microns to several tenths. This means that, initially, the cotton filter has a low filtering power (equal to 50% of a contaminant with a range of between 5 and 200 μ). Only after a dust cake forms on the surface does the filtering power increases up to 80% of the above-‐mentioned range, but there is a resultant drastic pressure drop. In short, a cotton filter has low filtering power for half of its lifetime, while for it’s remaining lifetime it has a very high pressure drop.

MICROSCOPE:

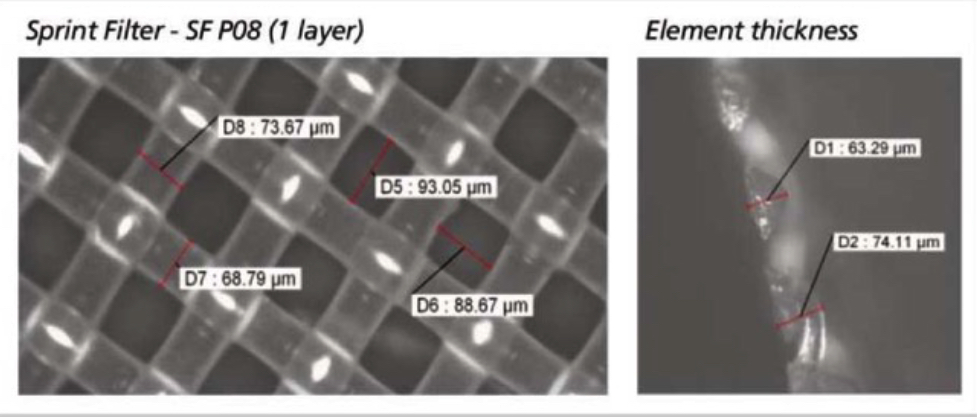

The homogeneous and compact filtering element consists of a thin filament of polyester fabric forming a mesh of a dozen of microns, capable of trapping all significant particles and ensuring a very high air flow.

EFFICIENCY

Many dyno tests have confirmed the importance of a flow with a minimum degree of impedance. A 4-‐cylinder 1000cc bike (fitted with a P08 filter) without any remapping of the control unit supplied more torque and 2.5 HP more at half the power curve, in that area that can guarantee a “fuller” response to the throttle.

In it’s engineering course, Trinity Saint David Swansea University tested the most popular motorcycle air filters on the market, checking the performance of each filter with a Super Flow flow bench. The test was set up in a simple but effective way: different brands of filters were fitted on a square section pipe, through which a set quantity of air was pushed. The curve distribution is evident: the polyester Sprint Filter filter definitely breaks away from the “group” of cotton filters (among which the Sprint Filter waterproof polyester filter ranks very well), and sponge filters are positioned at the bottom of the chart. The structure of the filtering elements was then checked under the microscope, and in this case as well the uniformity and compactness of the polyester were obvious.

Analysis of the P08 filtering element with 10x. Fibre thickness= 68 μm -‐ Mesh area= 8184 μm2

MAINTENANCE:

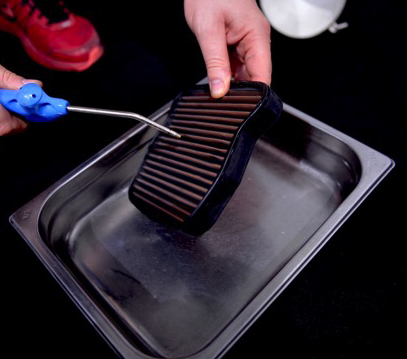

Maintenance of the air filter is important for the protection, care and efficiency of the engine. A clean and undamaged filter will always ensure the correct quantity of clean air for the air-‐box. Another air filter maintenance aspect not to disregard is how long it lasts. Apart from the time required for disassembly and reassembly, cotton filters demand downtime for washing, drying and oiling the filtering element, all operations not necessary with a polyester filter. The Sprint Filter air filter cleaning procedure is, in fact, extremely easy and quick: just use an air jet in the opposite direction of the suction to remove most of the debris collected. No washing or drying is necessary, so it can be refitted straight away. For exceptionally dirty filters begin with compressed air, then using a common household detergent, allow the filter to soak for 15-‐30 minutes and gently agitate the filter in the solution. Rinse the filter with clean water until the water runs clear. Allow to air dry thoroughly and then reinstall. Reminder, Do Not Oil.

A FILTER WHATEVER THE NEED

P08 -‐ P16 -‐ P08F1-‐85 -‐ P037: A FILTER THAT MEETS ALL REQUIREMENTS

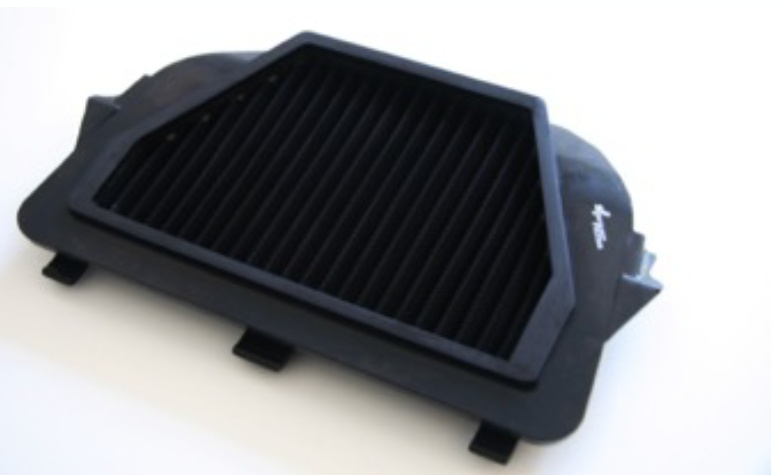

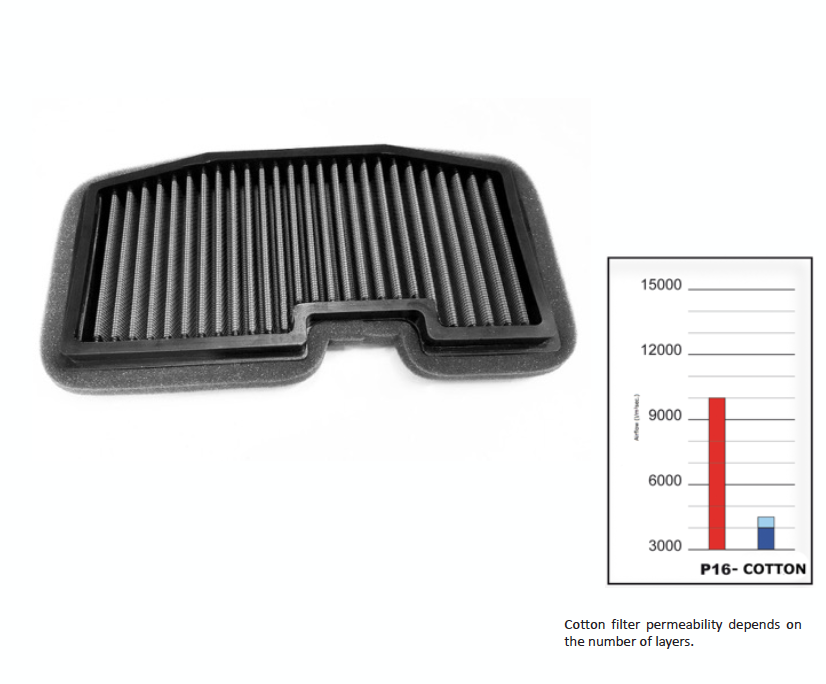

Sprint Filter P08 Single layer of polyester for road & track use. High airflow: 5,050 l./m2sec.

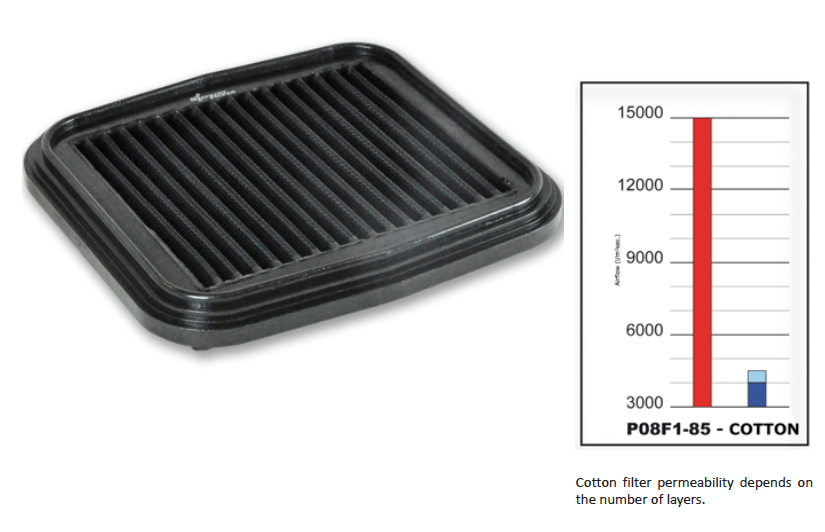

Sprint Filter P16 Single layer of polyester only for racing use. Very high airflow: 10,000 l./m2sec. Sprint Filter P08F1-‐85 Single layer of waterproof polyester, currently used in MotoGP and WSBK. Extremely high airflow >15,000 l./m2sec. with a very good filtration power.

Sprint Filter P08F1-‐85 Single layer of waterproof polyester, currently used in MotoGP and WSBK. Extremely high airflow >15,000 l./m2sec. with a very good filtration power.

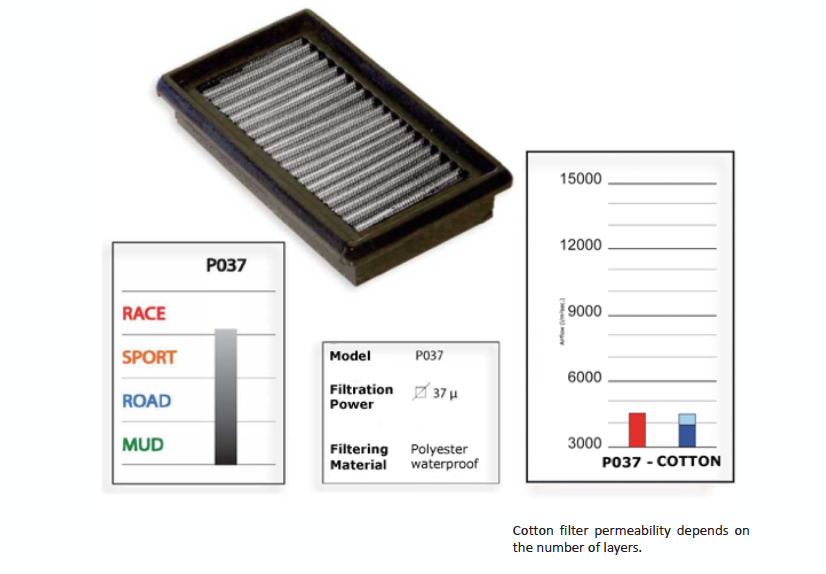

Sprint Filter P037 (specific for DUAL SPORT) Single layer of waterproof polyester, perfect for Dual Sport motorcycles (like the BMW GS1200, Ducati Multistrada). Airflow: 4,500 l./m2sec.

FACTORY KITS Special intakes which considerably increase considerably the max power and top speed. These kits are dedicated only to racing fairings and are made in carbon fibre or avio fibre, to be used in compliance with the FIM STK rules

FACTORY KITS Special intakes which considerably increase considerably the max power and top speed. These kits are dedicated only to racing fairings and are made in carbon fibre or avio fibre, to be used in compliance with the FIM STK rules

Sprint Filter P08

Filtration degree 80 micron, with guaranteed air flow of 5,000 l/m2sec. figures make the P08 a very versatile and efficient air filter, suitable for use on the road but with outstanding performance characteristics. Dyno testing of a 4-‐cylinder 1.000cc bikes without control unit remapping, revealed an extra 2.5 HP halfway through the power curve. They are available for a wide range of motorbikes and scooters.

Sprint Filter P16

This type of filter has very high permeability that guarantees the exceptional air flow of 10,000 l/m2sec. while at the same time retaining adequate filtering power. This model, suitable for the track, is used by a large number of teams taking part in various speed championships, because of the unquestionable qualities of the filter and the performance.

Sprint Filter P08F1-‐85

Developed and used by the leading Factory Teams in MotoGP and WSBK, P08F1-‐85 is the latest technological advancement from Sprint Filter with the highest existing permeability of any air filter on the market (allowing an impressive air flow of >15,000 l/m2sec.), guaranteeing a filtering power of 85 μm that makes it even more exclusive. All these features make P08F1-‐85 an air filter particularly suitable for racing, but with the special Sprint Filter technology it can also be used on the most sophisticated latest generation of 600cc and 1000cc supersports bikes that, in most cases, do not need carburation adjustment with special mapping of the ECU or additional control units. However, their use taps 100% of the potentials of this technological jewel.

Sprint Filter P037

P037 and the P08F1-‐85 are the only air filter in the world with waterproof characteristics (Sprint Filter patent, meaning SF is the only air filter manufacturer in the world that produces waterproof air filters for internal combustion engines). The weave of the fabric guarantees an amazing filtration power of 37μm, that, combined with its waterproof properties, makes this type of air filter particularly suitable for use in demanding conditions with the presence of mud (no sand or fine dust). The guaranteed air flow of 4,500 l/m2sec. made a BMW GS1200 only with an aftermarket exhaust fitted and P037 air filter to be the fastest BMW GS1200 in the world, clocking 233.35 km/h at the Bonneville Salt Flats located in Utah, USA.

CARBON FIBRE AIR FLTERS DESIGNED FOR THE DUCATI PANIGALE

Fits models: 899, 959, 1199, PanigaleR, Superleggera1 (except 1299 Superleggera)

Sprint Filter has designed a special air filter with carbon fibre or avio fibre (special fibreglass made with the autoclave process) external structure for all Ducati Panigale models to decrease the weight and increase the stiffness of the structure. The filtering membrane, consisting of the P08, P16 or P08F1-‐85 fabrics, has a larger surface area than the original (+210%) that, together with the specific permeability of the various Sprint Filter fabrics, guarantees unrivalled air delivery to the air box. The filters clasp directly to the Ducati Panigale frame without any modification, so both the original air filter and filter holder are eliminated.

SPRINT FILTER SPECIAL FACTORY KITS (WITHOUT AIR FILTER)

Sprint Filter has completely redesigned the fluid dynamics of some superbikes by designing some air inlet + instrument holder frame kits that, on their own, increase the maximum speed considerably. These kits are designed only for racing fairings without headlamps and are made in both carbon fibre or avio fibre, to be used in compliance with the FIM STK and SBK regulations for the single categories. The BMW S1000RR kit is used by the Althea BMW Racing team in the WSBK and STK1000 World Championship, the Ducati Panigale kit by the Barni Ducati team in the Italian Speed Championship (CIV), and the Yamaha R1 kit by the top Sprint Filter development teams. The kits are built for the racing fairings of all makes, and are supplied without any fixing holes for better adaptation.

SPRINT FILTER FACTORY KITS (WITH AIR FILTER)

Sprint Filter has introduced a revolutionary new product for racing: the Factory Kit. It consists of the special air funnels in coated fibreglass with kevlar reinforcements is suitable for racing fairings only and is profiled so as to eliminate any obstacle to the clean laminar flow, so it is able to guarantee air flow of 10,000 l/m2sec., a very high value that lets the Sprint Filter funnels to be exploited to the fullest. This product, available for the most popular latest generation of Super Sport 600cc and 1000cc bikes, is the result of many years of testing and improvements carried out by Sprint Filter in close collaboration with some of the main Racing Departments in its role of sole supplier. These kits may require some modification for installation.

- Published in Conquest Racing Parts

SC Project Exhaust Dealer UK

SC Project Exhaust Dealer UK

Welcome to Conquest Racing Ltd, we are proud UK dealers for SC Project exhausts

SC Project Exhaust Dealer UK SC-Project – A factory with the leadership in the manufacture of premium motorbike exhaust systems, we are strongly settled in the racing world and this guarantees the final customer the highest performance without compromises. SC-Project’s commitment in the racing world is set in a world contest in the championships of the highest level as in MotoGP, SBK, Moto2 and Moto3 World Championship and in the most important motorbike Championships. Top performances, reliability and the most advanced technology are the components which allow experience exchange between the R&D department (research and development) and the several World Championship teams, guaranteeing the final customer a top-level product as regards performance, material quality, and trim level. The experience and know-how acquired in worldwide races together with several tests on test bench guarantee excellence both in race world and private world in the street.

Only companies with top-level technologies and capabilities can be the supplier of MotoGP teams, where the highest technical competences, constant evolution and development are requested for the strongest and most competitive worldwide riders and teams. This technology is then used to produce SC-Project exhaust systems for customers for normal road use, supplying a wide range of silencer models and complete exhaust systems. SC-Project is the Moto2 World Champion exhaust with the rider Johann Zarco in the 2015 and 2016 season.

Zarco, Qatar Moto2 Test 2016

In 2016 SC-Project is the official technical supplier of exhaust systems for the Italian MV Agusta in the World Superbike Championship with its national team “Racing Department”, which will field in the superlative SBK MV Agusta F4 RC with the British rider Leon Camier and in the Supersport performance F3 RC 675 driven by the talented Frenchman Jules Cluzel, already fighting for the world title in 2015 riding the F3 Supersport, and the young Italian Lorenzo Zanetti, for the second consecutive year with MV Agusta. In SBK also continue the collaboration with Kawasaki Pedercini team with the bike ZX-10R 2016.

In MotoGP 2016 is the exhaust supplier for Honda HRC team Estrella Galicia 0,0 Marc VDS with the rider Jack Miller and Tito Rabat, and in Moto2 is the supplier of the World Champion Johann Zarco, and other 5 riders like Lorenzo Baldassari, Luca Marini, Luis Salom, Jesko Raffin and Efren Vazquez. The partnership with important racing teams allows SC-Project to get a very important technical experience and to test the ultimate products and material. The same technology acquired and developed in the World championship is then transferred to common road products destined to our private customers and selling in our catalog.

Technology and excellence, with no compromise, that is our philosophy.

SC Project Exhaust Dealer UK

- Published in Conquest Racing Parts

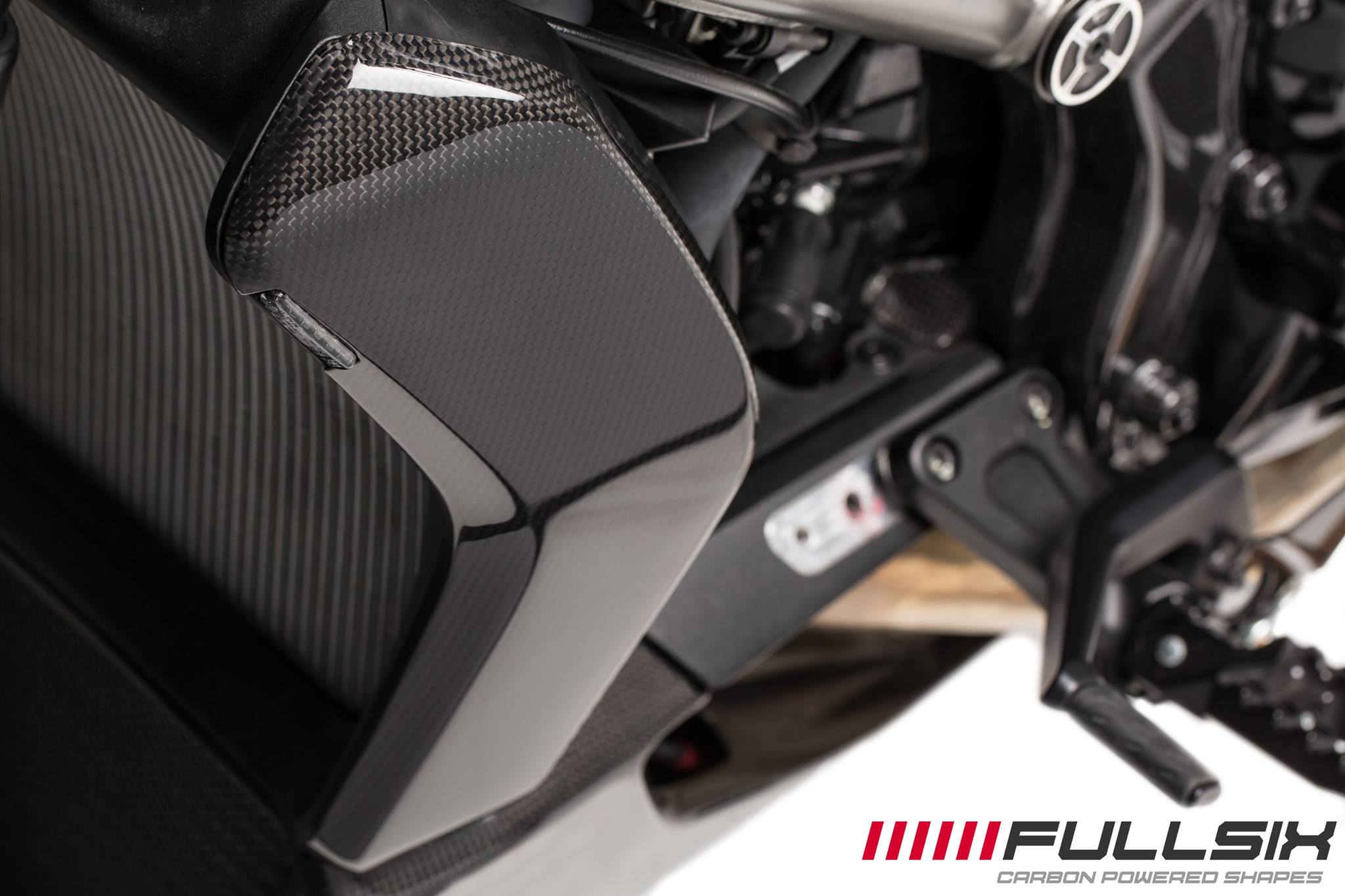

Ducati XDiavel Carbon Fibre Parts – Fullsix Carbon

Ducati XDiavel Carbon Fibre Parts – Fullsix Carbon

Now available Ducati XDiavel carbon fibre parts made by the worlds best carbon fibre manufacturer

FULLSIX CARBON

Fullsix carbon fiber parts guarantee an excellent appearance and perfect manufacturing. By using state-of-the-art technology and an innovative blend of materials, we assure you that our parts will upgrade your motorcycle both visually and in terms of performance. We have paid particular attention to ensuring that all carbon fiber parts are UV protected through the use of special lacquers, as we know that our customers desire eternal beauty and perfection.

The uniqueness of our products is not just an advertising slogan, but the underlying philosophy of our company itself. Since we believe in providing only the best for your motorcycle, we have developed a unique production monitoring system that ensures that all Fullsix products are manufactured according to the latest protocols and “best-in-the-industry” standards. Through the use of unique barcode technology, CDT Group is the only company in the market that is capable of tracing products through the entire manufacturing process, resulting in products that you can completely trust.

Fullsix stands for perfect looks, precise fitting, outstanding performance and supreme quality.

- Published in Conquest Racing Parts

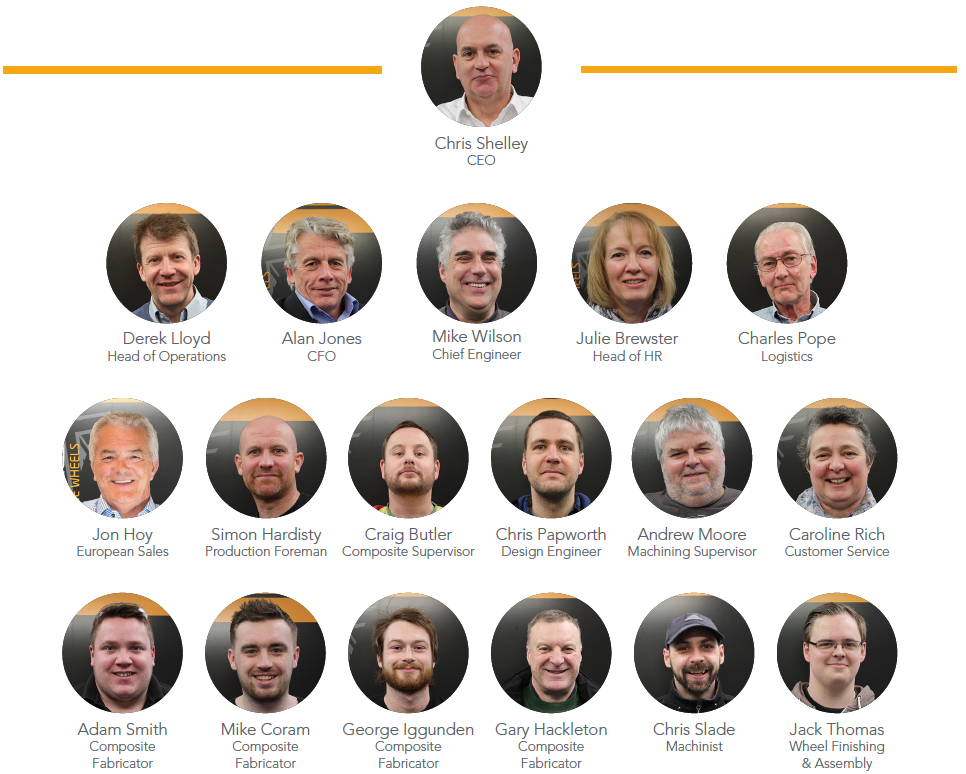

Dymag Racing Performance Wheels

Dymag Racing Performance Wheels

CONTENTS

Dymag Brand 1.0

Racing 2.0

Sponsored Events 3.0

HQ 4.0

Best of British 5.0

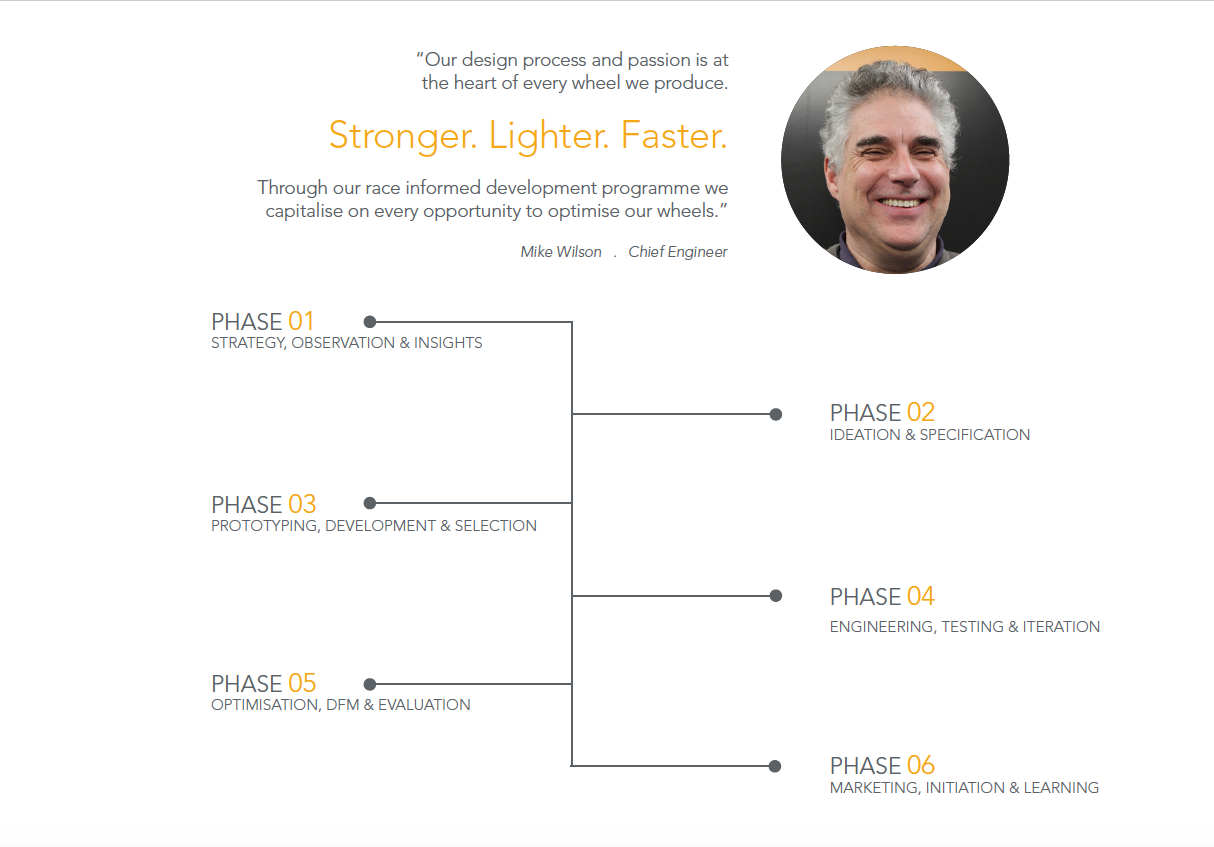

Design Process 6.0

Technology & Innovation 7.0

Marketing Communication 8.0

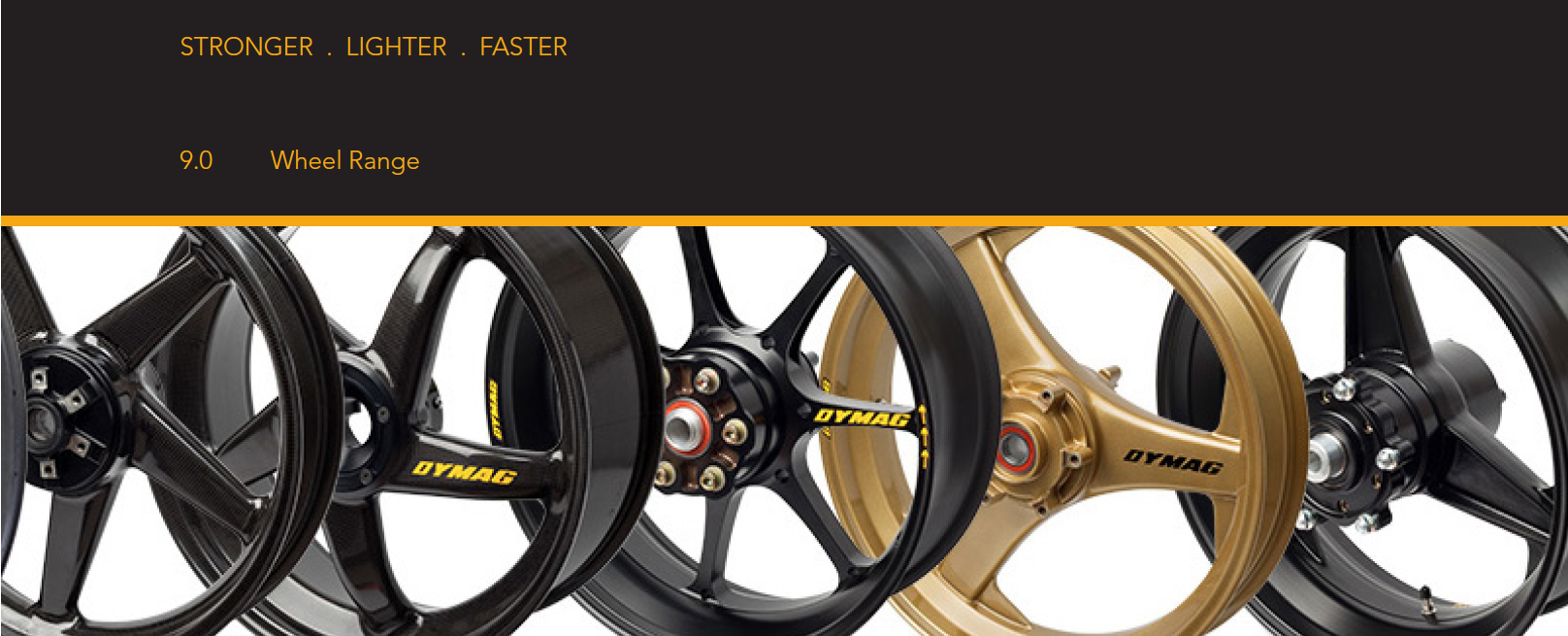

Wheel Range 9.0

Testimonials 10.0

40 YEARS IN ELITE MOTORSPORT

FORMULA ONE. INDY CAR. GT RACING. LE MANS 24h. TOURING CAR. WRC. PARIS DAKAR. GP500. SBK. ISLE OF MAN TT

1975 – 94 Dymag invent world’s first 3 spoke magnesium moto racing wheel. Dymag wheels in Formula One (Senna, Prost, Mansell) Indy Car, RAID, WRC.

1990’s Dymag launch world’s first one piece and two piece carbon composite moto wheels certified for road and racing use.

2004 Dymag launch world’s first commercial carbon composite auto wheel.

2011 Focus returns to aftermarket composite and forged moto wheels.

2014 Dymag wheels on triple IOMTT winning team Hawk Racing / Buildbase BMW Motorrad with rider Michael Dunlop. 2015 Dymag launches first new carbon composite auto wheel for 10 years at SEMA, Las Vegas.

2016 Continued support to works IOM TT & SBK teams including Michael Dunlop’s campaign.

DYMAG – LEADING THE WORLD IN WHEEL INNOVATION AND PERFORMANCE

Dymag is a company with its heritage firmly rooted in racing. Started in the early 1970’s, we quickly established a reputation for pioneering innovation inventing the world’s first 3-spoke magnesium motorcycle racing wheel. These ground-breaking wheels were ridden by the legendary Eddie Lawson to overall victory in the AMA Superbike Championship in both 1981 and 1982 and the Moto GP Championship in 1984.

Dymag was the first company in the world to manufacture carbon fibre wheels for both high performance motorcycles and cars certified for road and race use. Uniquely, Dymag manufactures wheels in high quality forged magnesium, aluminium and lightweight carbon fibre. We also offer over 3,000 individual fitments for a huge range of motorcycles. We believe no other company has the capability and technology to do this.

WE’RE BACK IN TOP LEVEL RACING

Continuing our tradition, for 2016 we’re partnering with a number of leading IOM TT, British Superbike & European Race Teams

2016 DYMAG FACTORY SUPPORTED PILOTS

ISLE OF MAN TT HAWK RACING / BUILDBASE BMW MOTORRAD – Michael Dunlop

QUATTRO PLANT / BOURNEMOUTH KAWASAKI – James Hillier

MAR-TRAIN YAMAHA – Dan Kneen RIDERS BMW – Martin Jessopp

BRITISH SUPERBIKE HAWK RACING / BUILDBASE BMW MOTORRAD – Lee Jackson & Richard Cooper

QUATTRO PLANT / BOURNEMOUTH KAWASAKI – Luke Mossey & Filip Backlund

GR MOTOSPORT / TEAM WD40 – Jack Kennedy & Sam Hornsey

RIDERS BMW – Martin Jessopp

CLASSIC TT TEAM CLASSIC SUZUKI – Michael Dunlop & Lee Johnston

PADGETTS MOTORCYCLES – Bruce Anstey & Dan Kneen

MOTO AMERICA SUPERBIKE KWR – Kyle Wyman

SPONSORED EVENTS

Dymag Golden Era Superbike Championship | Thundersport GB Series

The Dymag Golden Era class supports pre-2000 year bikes of 750, 950 and 1000cc capacities and will be televised on Motors TV.

This is Dymag’s first series sponsorship reflecting the importance that this level of racing holds, not only for rider development but also to showcase what is for many, the golden age of superbike racing.

As all Dymag wheel specifications and materials are permitted in the Golden Era class, we have the opportunity to create a real heritage moment for Dymag, showcasing the technical quality and competitive edge that our wheels deliver

“We are on track with our growth plans and expanding our composite wheel manufacturing into a state of the art facility with support from UKTi and the government’s Advanced Manufacturing Supply Chain Initiative (AMSCI). With technical support from the NCC we are designing, installing and commissioning the very latest composite manufacturing process equipment.

Thanks to this ground breaking partnership, Dymag has access to the NCC’s composite expertise in the aerospace, marine and automotive industries.” Chris Shelley CEO Dymag Group Ltd

“We are thrilled to be able to bring composites manufacturing support to Dymag Performance Wheels Limited at this exciting time as they develop their business to provide higher volume manufacturing technologies.” Tom Hitchings Business Development Director, National Composite Centre

PROUD TO BE BRITISH

We have been designing and manufacturing auto and moto wheels for over 30 years from our UK base in Wiltshire, England. Whilst the technology that goes into every wheel has evolved, our relentless commitment to quality and design remains at the core of every wheel we make.

HERITAGE & INNOVATION

Originally manufacturing gravity die-case magnesium wheels from which the company grew its name “Dy-mag”, we have continually sought to utilise the most advanced materials and latest manufacturing technology.

RACING SUCCESS

All our racing, aftermarket and OEM wheels have been developed in elite motorsport applications and adapted for road use. Our latest prototyping workshop, and cutting edge CAD and fluid dynamics software are enabling us to develop race wheels of the future.

LOW MOMENT OF INERTIA (MOI)

All Dymag wheels are born from the same meticulous design process, including a thorough engineering & optimisation phase where all unnecessary material (where durability will not be impacted) is carved away. The result is a range of wheels with a super low moment of inertia. Design for low MOI reduces the amount of energy required to overcome inertia resulting in vastly improved acceleration, braking & directional changes > low MOI offers supreme handling.

LIGHT WEIGHT

The light weight nature of all Dymag wheels utilising low density materials offers a huge reduction over original equipment (OE) wheels. Newton told us that a force (provided by your right hand) acting on a body of lower mass (Dymag wheels) will accelerate faster than the competition. We trust Newton.

STATE OF THE ART TECHNOLOGY

Our new carbon composite facility in the heart of the Wiltshire countryside, employs state-of-the art production technology. We are capable of mass production volume with improved finished detail. The resolution that Dymag has become known for drives our technology, including our composite modulus refinement programme.

MARKETING COMMUNICATION

We love keeping our customers up-to-date with our latest news, product specifications and technology information. Everything is on our website at www.dymag.com and you can also follow us on Facebook, Twitter and Instagram. Look for our wheels in action on our dedicated YouTube channel.

We fly the Dymag flag at exhibitions and special events worldwide as we continue to grow our global dealer network.

Dymag achieves regular, targeted coverage in leading online and print platforms and we in invest in aspirational advertising. Dymag wheels score highly in long term tests, proving that durability is a high priority in every Dymag designed wheel as well as achieving dramatic weight savings over OE wheels.

Yamaha Europe ‘Yard Built’ series and other special projects remain an important channel of communication, enabling us to promote our design flexibility and vision, while remaining honest to the Dymag brand.

THE DYMAG WHEEL RANGE

In addition to our rigorous in-house testing, all Dymag wheels are certified to BSAU50, SAE and JWL standards for road and race applications. This means that our professional specification, race-winning wheels are the very same wheels that you can buy for your own road or track bike.

By using our own modular aluminium hub design, Dymag are able to offer over 3000 individual fitments, from a 1985 Suzuki RG500 to a 2016 Kawasaki ZX-10R. Complete wheelsets are delivered fully assembled with valves, spacers, high quality bearings and your specified sprocket ready for you to fit your tyres and discs and get out riding. We also offer a ceramic bearing upgrade on certain applications.

All of our rear wheels are assembled with Dymag’s proprietary cush drive & sprocket carrier and a Talon sprocket. We carry a full compliment of spare parts for our wheels and offer an in-house wheel refurbishment service which includes crack testing and refinishing. Dymag will never repair a lightweight wheel that has been more than superficially damaged.

Dymag offer a Satin Black powder coat as standard for all carriers and non-carbon wheels, with the option to upgrade to a custom colour. An anodised finish is offered in several colours for carriers within carbon wheel sets only and our CA5 carbon wheels always retain a polished weave finish.

CA5 . CARBON COMPOSITE

Produced by in-house skilled technicians at our UK composite production facility, using proprietary cloth and lay up orientation. We refine the modulus of the composite and therefore tailor the stiffness and compliance of the CA5 wheel body.

Polished clear weave finish, with anodised or painted hubs. Available for single sided swing arms as well as standard double sided.

SIZES Front: 16.5” x 3.50” 17” x 2.50” / 3.50” / 3.75”

Rear: 16.5” x 6.25” (double sided only) 17” x 5.50” / 6.00”

TYPICAL ASSEMBLED WHEEL WEIGHTS

APRILIA RSV4 front: 2.53kg rear: 4.83kg

SUZUKI GSXR1000 front: 2.54kg rear: 4.92kg

HONDA CBR1000 RR front: 2.57kg rear: 4.65kg

UP7X . FORGED ALUMINIUM ALLOY

Forged using high quality aluminium alloys which then undergo stress relieving grain refinement. UP7X is ‘the thinking man’s wheel’ – the wheel that’s been ridden by professionals to numerous IOM TT & SBK wins.

Powdercoat paint finish in-house.

Available for double sided swing arms only.

SIZES Front: 17” x 3.50”

Rear: 17” x 5.50” / 6.00”

TYPICAL ASSEMBLED WHEEL WEIGHTS

BMW S1000 HP4 front: 3.15kg rear: 5.80kg

SUZUKI GSXR1000 front: 3.32kg rear: 5.96kg

HONDA CBR1000 RR front: 2.95kg rear: 5.72kg

CH3 . CAST MAGNESIUM ALLOY

Magnesium has always been at the heart of Dymag and the CH3 embodies our heritage and knowledge of casting this material. Ever popular with classic enthusiasts, CH3 offers ultimate performance in a wide range of fitments for both modern and classic bikes.

Powder coat paint finish in-house.

Available for double sided swing arms only.

SIZES Front: 17” x 3.00” / 3.25” / 3.50” 18” x 2.50” / 2.75”/ 3.00” / 3.25” / 3.50” 19” x 2.50”

Rear: 17” x 4.50” / 4.75” / 5.00” / 5.50” / 6.00” / 6.25” 18” x 3.00” / 3.25” / 3.50” / 3.75” / 4.00” / 4.25” / 4.50” / 4.75” / 5.00”

TYPICAL ASSEMBLED WHEEL WEIGHTS

APRILIA RS250 front: 3.53kg rear: 5.70kg

YAMAHA YZF R1 front: 3.70kg rear: 6.00kg

TT3 . CAST MAGNESIUM ALLOY

Our hollow three spoked magnesium design ensures as much weight saving as possible without compromising on durability or performance, being designed specifically for the extreme racing environment in the Isle of Man TT Races and World Endurance Superbikes. All wheels are suitable for on road and racing use.

Powder coat paint finish in-house.

Available for single sided swing arms as well as standard double sided.

SIZES Front: 16.5” x 3.00” / 3.25” / 3.50” / 3.63” / 3.75” 17” x 3.00” / 3.25” / 3.50” / 3.63” / 3.75” 18” x 2.50 “ / 2.75” / 3.00” / 3.25” / 3.50”

Rear: 16.5” x 5.25” / 5.50” / 6.00” / 6.25” 17” x 4.00” / 4.25” / 4.50” / 4.75” / 5.00” / 5.25” / 5.50” / 6.00” / 6.25” 18” x 4.00” / 4.25” / 4.50” / 4.75” / 5.00”

TYPICAL ASSEMBLED WHEEL WEIGHTS

HONDA RC45

front: 3.40kg rear: 3.87kg

SB5 . CAST MAGNESIUM ALLOY

The five hollow spoked design magnesium wheels have been designed with performance motorcycle racing, OE and aftermarket applications in mind.

Powdercoat paint finish in-house.

Available for double sided swing arms only.

SIZES Front: 16.5” x 3.00” / 3.25” / 3.50” / 3.63” / 3.75” 17” x 3.00” / 3.25” / 3.50” / 3.63” / 3.75”

Rear: 16.5” x 5.25” / 5.50” / 6.00” / 6.25” 17” x 5.00 / 5.25” / 5.50” / 6.00” / 6.25”

TYPICAL ASSEMBLED WHEEL WEIGHTS

APRILIA RSV4

front: 2.53kg rear: 4.83kg

SUZUKI GSXR1000

front: 2.54kg rear: 4.92kg

HONDA CBR1000

front: 2.57kg rear: 4.65kg

“We are extremely proud to re-kindle our association with Dymag, I have known Chris Shelley for many years, right back to when he supported me through the European Championships, which I went on to win, so when we decided to go back into British Superbikes, the decision to run with the UP7X aluminium wheel was a no-brainer as they simply are the best, and we know Dymag will never let us down.” Brent Gladwin Principal, Team WD40 “

“Quattro Plant Kawasaki BSB and IOM TT Team have opted for known quality in its wheel choice for its assault of the BSB Championship in 2014 , Dymag UP7X were an obvious choice for the team with the product being great quality and value for money, Not to mention the superb back up service available in the UK.” Pete Exstance Principal, Team Quattro Plant Bournemouth Kawasaki

“When we decided to take KWR into the Moto America Superbike series for 2016, we were looking for new partners that could help us build the best bike possible. Now that we are working with Dymag and running the UP7X wheels on our Yamaha R1, I’m confident that we have a big piece of our puzzle in place. I am looking forward to my Superbike rookie season and am excited to have Dymag in my corner.” Kyle Wyman KWR Racing

- Published in Conquest Racing Parts

MV Agusta Dragster 800 Carbon Fibre Parts

MV Agusta Dragster 800 Carbon Fibre Parts

Manufactured using pre-preg carbon fibre & steel moulds then cured in a high temperature autoclave oven creating a much thinner, lighter product without compromising on strength.

Fits Models: MV Agusta Dragster

Auto-clave production produces the best finish on the weave, keeping the carbon fibre in a more level and constant pattern, preventing kinks and stretching. Finally laser cut using a high pressure water jet to produce a clean edge & polished by hand.

Using 200 gram, 3K plain weave carbon fibre with an epoxy resin, providing both excellent strength and flexibility, UV treated lacquer which will help to keep your carbon fibre looking new.

Features:

– High quality clear finish will add a custom, race look to your bike

– Made by using high quality epoxy resin and high quality carbon fibre

– Auto clave produced

– Available in gloss

– UV resistant varnish

– Same OEM MV CRC carbon fibre weave

– Make your bike stand out from the crowd

- Published in Conquest Racing Parts

Rizoma Motorcycle Billet CNC Accessories UK dealer

Rizoma Motorcycle Billet CNC Accessories UK dealer

HISTORY OF THE BRAND

“I cannot find this accessory for my bike anywhere, why don’t you make it for me?”

That could have been the beginning of the story, which in just over 10 years has transformed the two bothers’ passion and creativity into a Premium Brand of motorcycle accessories and design products, made of exclusive quality materials, such as aluminium and composite fibres.

Over the years, Fabio and Fabrizio Rigolio (General Manager and CEO of Rizoma) have managed to build up a young and dynamic team able to manufacture and trade worldwide the objects, which impress everyone with their elegant and original design and with their maniacal quality.

RIZOMA, STYLE & DESIGN

The unmistakable style of Rizoma is summarised in the pure lines of its products, which give the object an elegant and refined minimalism.

BILLET ALUMINIUM

Beginning with a solid block, the aluminium moulds itself and becomes an effusive element made of emotions and sensations. “You see a block, think about the image; the image is inside. You only have to undress it.” Michelangelo Buonarroti

RIZOMA PEOPLE

The strength of Rizoma lies in the

passion of those who created it and

those who work there every day: ideas and diligence are fundamental for a “Made in Italy” product which is world famous for the high quality and the attention to its details.

- Published in Conquest Racing Parts